Yinii-arc welding ene-flux-cored?

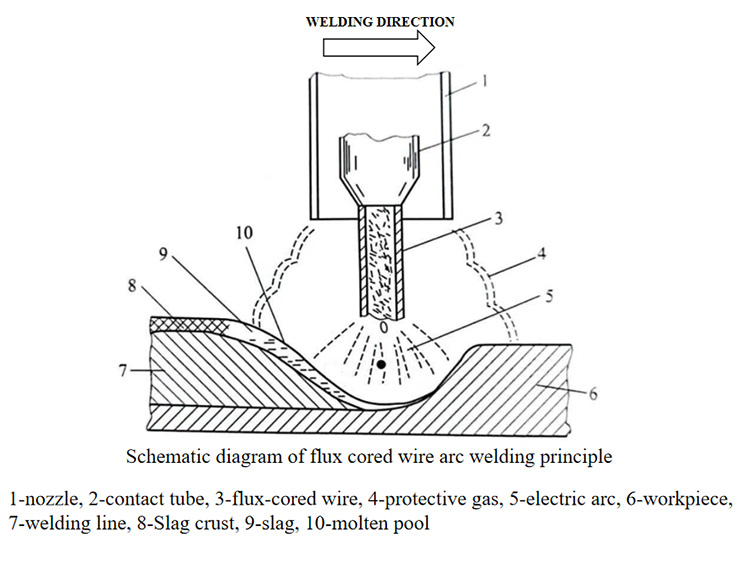

I-Flux-cored wire arc welding iyindlela yokushisela esebenzisa i-arc phakathi kwentambo ene-flux-cored kanye nendawo yokusebenza ukuze kushiswe, futhi igama layo lesiNgisi limane nje lithi FCAW.Ngaphansi kwesenzo sokushisa kwe-arc, i-welding wire metal kanye ne-workpiece ixhunywe ngokuncibilika, ukwakha i-weld pool, i-arc phambili ngemva kokucwebezeliswa komsila we-weld pool.

Iyini i-flux-cored wire?Yiziphi izici ze-cartridge?

I-Flux-cored welding wire iwuhlobo lwentambo yokushisela eyenziwe ngokugingqa umucu wensimbi omncane ube yipayipi lensimbi noma ipayipi lensimbi elimise okukhethekile, ukugcwalisa ipayipi ngezinto ezithile zempushana, kanye nomdwebo.Ukwakheka kwe-powder core kufana nalokho kwe-electrode coating, ikakhulukazi eyakhiwe i-arc stabilizing agent, i-slag forming agent, i-gas forming agent, i-alloying agent, i-deoxidizing agent, njll.

Ithini indima yokuguquguquka ocingweni olune-flux-cored?

Indima ye-flux ifana neye-electrode coating, futhi kukhona ikakhulukazi izinhlobo ezilandelayo.

① Umthelela ovikelayo wezinye izingxenye ekuboleni kwe-welding flux, okunye ukuncibilika!Ukubola kwe-welding flux kukhipha igesi, enikeza ukuvikeleka okuthile noma okuningi.I-flux encibilikisiwe yenza i-slag encibilikisiwe, emboza ingaphezulu leconsi nechibi elincibilikisiwe, futhi insimbi ewuketshezi iyayivikela.

② I-arc stabilizer ku-arc stabilizer cartridge ingasimamisa i-arc futhi yehlise izinga lokufafaza.

③ Isenzo se-alloying Ezinye zezakhi ze-alloy kumongo zingahlanganisa i-weld.

④ Izakhi ze-deoxidation ze-slag zingasabela ngezinsimbi eziwuketshezi.Thuthukisa ukwakheka kwensimbi ye-weld, uthuthukise izakhiwo zayo zemishini.

Ngaphezu kwalokho, i-slag embozwe inganciphisa izinga lokupholisa lechibi elincibilikisiwe, ikhulise isikhathi sokuba khona kwechibi elincibilikisiwe, okuzuzisa ukunciphisa okuqukethwe kwegesi eyingozi ekushiseleni futhi kuvimbele i-porosity.

Yiziphi izinhlobo ze-flux cored arc welding ezikhona?

Kunezinhlobo ezimbili ze-flux cored wire arc welding (FCAW-G) kanye ne-self-protection welding (FCAW-S), kuya ngokuthi igesi yokuvikela yangaphandle iyasetshenziswa noma cha.

Igesi evikelwe ngegesi yocingo olunamathambo ngokuvamile isebenzisa i-carbon dioxide noma i-carbon dioxide kanye ne-argon njengegesi evikelayo, futhi ukugeleza kwentambo kuqukethe i-ejenti encane yokukhipha igesi.Le ndlela ifana ne-welding evamile yegesi evikelekile.I-welding yokuzivikela ayidingi igesi yangaphandle yokuzivikela.Kunenombolo enkulu ye-gasifier ekuguquguqukeni, futhi igesi ne-slag eboliswe i-gasifier isetshenziselwa ukuvikela.

Yiziphi izinzuzo ze-flux-cored arc welding?

I-Flux-cored arc welding inezinzuzo ezilandelayo.

(1) Ukukhiqiza okuphezulu kwe-welding ephezulu yokuncibilika kahle (kufika ku-85% ~ 90%), isivinini sokuncibilika okusheshayo;Ukuze uthole i-flat welding, ijubane lokunamathela liphindwe izikhathi ezingu-1.5 kune-arc welding manual, kanti kwezinye izikhundla zokushisela, liphindwe izikhathi ezingu-3-5 kunelo lokushisela i-arc manual.

② I-splash encane, i-weld eyenza umuthi omuhle we-arc stabilizer, ngakho-ke ukuzinza kwe-arc, i-splash encane, ukwakheka okuhle kwe-weld.Ngenxa yokuthi ichibi elincibilikisiwe limbozwe nge-slag encibilikisiwe, ukuma kwe-weld surface kungcono kakhulu kunokwe-carbon dioxide welding.

(3) Ikhwalithi ephezulu yokushisela Ngenxa yokuvikelwa okuhlangene kwegesi ye-slag, ingavimbela ngokuphumelelayo igesi eyingozi ukuthi ingangeni endaweni yokushisela.Ngaphezu kwalokho, isikhathi sokuba khona kwechibi elincibilikisiwe side, esivumela ukuna kwegesi, ngakho-ke i-weld inokuqukethwe kwe-hydrogen ephansi kanye nokumelana okuhle kwe-porosity.

(4) Ukuzivumelanisa nezimo okuqinile kudinga kuphela ukulungisa ukwakheka kwe-solder wire cored, kungahlangabezana nezidingo zezinsimbi ezahlukene ekubunjweni kwe-weld.

Yibuphi ububi be-flux-cored arc welding?

Ukushiyeka kwe-flux-cored arc welding kanje.

Uma kuqhathaniswa ne-welding evikelekile yegesi, izindleko zocingo lokushisela ziphezulu futhi inqubo yokukhiqiza iyinkimbinkimbi.

② Ukuphakela ngocingo kunzima, kuyadingeka ukusebenzisa umshini wokuphakela ngocingo okucindezelwa kwawo kwe-clamping kungalungiswa ngokunembile.

③ I-cartridge kulula ukumunca umswakama, ngakho-ke kuyadingeka ukugcina intambo yokushisela ngokuqinile.

④ Ukususwa kwe-slag kuyadingeka ngemva kokushisela.

⑤ Intuthu eyengeziwe kanye namagesi ayingozi akhiqizwa ohlelweni lokushisela, ngakho-ke umoya kufanele uqiniswe.

Iyiphi igesi yokuvikela evame ukusetshenziswa ekushiseleni i-arc ene-flux-cored?Yiziphi izici zento ngayinye?

I-Flux cored wire arc welding ngokuvamile isebenzisa igesi ye-carbon dioxide ehlanzekile noma i-carbon dioxide ne-argon gas njengegesi evikelayo.Uhlobo lwegesi ludinga ukukhethwa ngokuya ngocingo olunama-flux-cored olusetshenzisiwe.

I-Argon i-ionized kalula, ngakho-ke kulula ukufeza ukuguqulwa kwe-ejection ku-argon arc.Lapho okuqukethwe kwe-argon kwengxube yegesi ingekho ngaphansi kuka-75%, i-flux cored wire arc welding ingafinyelela uguquko oluzinzile lwe-jet.Ngokuncipha kokuqukethwe kwe-argon, ukujula kokungena kuyanda, kodwa ukuzinza kwe-arc kuncipha futhi izinga le-spatter liyakhula.Ngakho-ke, ingxube yegesi efanele ingu-75%Ar+25%CO2.Ngaphezu kwalokho, i-Ar+2%O2 nayo ingasetshenziselwa ingxube yegesi.

Uma igesi ye-CO2 ehlanzekile ikhethiwe, izobola ngaphansi kwesenzo sokushisa kwe-arc futhi ikhiqize inani elikhulu lama-athomu oksijini, okuzokwenza i-oxidize i-manganese, i-silicon nezinye izakhi echibini elincibilikisiwe, okuholela ekushisweni kwezakhi ze-alloying.Ngakho-ke, ucingo lokushisela olune-manganese ephezulu kanye nokuqukethwe kwe-silicon kufanele kusetshenziswe.

Isikhathi sokuthumela: May-09-2023