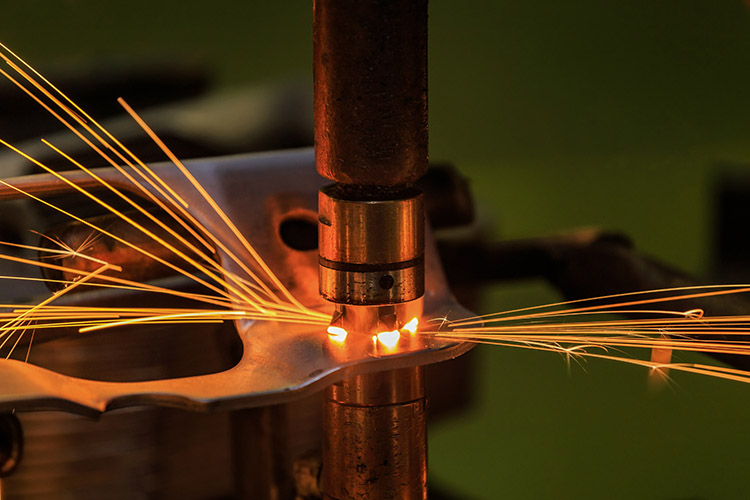

I-Spot welding iyindlela yokumelana ne-welding lapho i-weldment ihlanganiswa ibe yi-lap joint futhi icindezelwe phakathi kwama-electrode amabili, futhi isisekelo sensimbi sincibilika ngenxa yokushisa kokumelana ukuze senze i-solder joint.

I-Spot Welding isetshenziswa kakhulu kulezi zici ezilandelayo:

1. I-Lap joint yezingxenye zokunyathela amashidi, njengekhebhu yemoto, inqola, isikrini sesikali sezinhlanzi sokuvuna, njll.

2. Ipuleti elincanyana kanye nezinhlaka zensimbi zesigaba nezakhiwo zesikhumba, njengezindonga ezisemaceleni nosilingi wamakalishi, amaphaneli ekhompathi yama-trailer, amafaneli ahlanganisa okokuvuna, njll.

3. Izikrini, amafreyimu esikhala nama-cross bar, njll.

Cokuhlukumezayo

Ngesikhathi sokushisela, i-weldment yenza i-lap joint futhi icindezelwe phakathi kwama-electrode amabili.Izici zayo eziyinhloko zimi kanje:

1. Isikhathi sokushisa sendawo yokuxhuma sifushane kakhulu ngesikhathi sokushisela indawo, futhi isivinini sokushisela siyashesha.

2. I-Spot welding isebenzisa amandla kagesi kuphela, futhi ayidingi izinto zokugcwalisa noma i-flux, igesi, njll.

3. Izinga lokushisela indawo liqinisekiswa ngokuyinhloko ngumshini wokushisela indawo.Ukusebenza kulula, izinga lemishini kanye ne-automation liphezulu, futhi ukukhiqiza kuphezulu.

4. Amandla okusebenza aphansi kanye nezimo ezinhle zokusebenza.

5. Njengoba amandla e-welding aqedwa ngesikhathi esifushane, i-current enkulu kanye nokucindezela kuyadingeka, ngakho-ke ukulawulwa kohlelo lwenqubo kuyinkimbinkimbi, umshini wokushisela unomthamo omkhulu, futhi intengo yemishini ilinganiselwe. phezulu.

I-6.Kunzima ukwenza ukuhlolwa okungabhubhisi kumajoyinti e-solder.

Inqubo yokusebenza

Ubuso be-workpiece kufanele buhlanzwe ngaphambi kwe-welding.Indlela yokuhlanza evame ukusetshenziswa ukuhlanza i-pickling, okungukuthi, ukuqoqa ku-acid eshisayo ye-sulfuric ene-concentration ye-10%, bese ugeza ngamanzi ashisayo.Inqubo ye-welding ethize imi kanje:

(1) Thumela i-workpiece ehlangene phakathi kwama-electrode angaphezulu nangaphansi omshini wokushisela bese ulibopha;

(2) ukufakwa kukagesi, ukuze izindawo zokuthintana zalezi zingxenye zokusebenza ezimbili zishiswe futhi zincibilike kancane ukuze zenze i-nugget;

(3) Gcina ingcindezi ngemva kokuba amandla enqanyuliwe, ukuze i-nugget ipholile futhi iqiniswe ngaphansi kwengcindezi yokwenza i-solder joint;

(4) Susa ukucindezela bese ukhipha ucezu lokusebenza.

Izici ezinomthelela

Izici eziyinhloko ezithinta ikhwalithi ye-welding yi-welding yamanje nesikhathi sokunika amandla, ingcindezi ye-electrode kanye ne-shunt, njll.

1. Isikhathi se-Welding samanje nesokunika amandla

Ngokusho kobukhulu be-welding current kanye nobude besikhathi sokunika amandla, ukushisela indawo kungahlukaniswa ngezinhlobo ezimbili: ukucaciswa okuqinile kanye nokucaciswa okuthambile.Ukucaciswa okudlula umsinga omkhulu ngesikhathi esifushane kubizwa ngokuthi ukucaciswa okunzima.Inezinzuzo zokukhiqiza okuphezulu, impilo ende ye-electrode, kanye ne-deformation encane ye-weldment.Ifanele izinsimbi zokushisela nge-conductivity engcono yokushisa.Ukucaciswa okudlula umsinga omncane isikhathi eside kubizwa ngokuthi ukucaciswa okuthambile, okunokukhiqiza okuphansi futhi kulungele izinsimbi zokushisela ezivame ukuqina.

2. Umfutho we-electrode

Ngesikhathi sokushisela, ingcindezi ekhishwa yi-electrode ekushiseleni ibizwa ngokuthi ingcindezi ye-electrode.Ukucindezela kwe-electrode kufanele kukhethwe ngendlela efanele.Uma ingcindezi iphezulu, i-shrinkage porosity kanye ne-shrinkage cavity engenzeka lapho i-nugget iqina ingaqedwa, kodwa ukumelana nokuxhumeka kanye nokuncipha kwamanje kwehla, okuholela ekushiseni okwanele kwe-weldment kanye nokuncipha kobubanzi be-nugget ye-nugget. inhlanganisela ye-solder.Amandla okuhlangana kwe-solder ayancipha.Ubukhulu bengcindezi ye-electrode bungakhethwa ngokuya ngezinto ezilandelayo:

(1) Impahla yokushisela.Ayanda amandla okushisa aphezulu wento.Okukhulu umfutho we-electrode odingekayo.Ngakho-ke, lapho ushisela insimbi engagqwali nensimbi engangeni ekushiseni, ingcindezi ye-electrode kufanele ibe phezulu kunaleyo yensimbi ephansi ye-carbon.

(2) Imingcele yokushisela.Ukuqina kokucaciswa kwe-weld, ingcindezi ye-electrode inkulu.

3. shunta

Ngesikhathi sokushisela indawo, i-current egeleza isuka ngaphandle kwesekethe enkulu yokushisela ibizwa ngokuthi i-shunt.I-shunt inciphisa ukugeleza kwamanje endaweni ye-welding, okuholela ekushiseni okunganele, okuholela ekwehleni okuphawulekayo kwamandla okuhlanganiswa kwe-solder futhi kuthinte ikhwalithi ye-welding.Izinto ezithinta izinga lokuphambukisa zifaka phakathi izici ezilandelayo:

(1) Ubukhulu bendawo yokushisela kanye nokugqagqana kwamajoyinti e-solder.Njengoba ibanga phakathi kwamalunga e-solder likhula, ukumelana ne-shunt kuyanda futhi izinga le-shunt liyancipha.Lapho i-pitch yechashazi evamile engu-30-50mm yamukelwa, i-shunt yamanje ithatha u-25% -40% yenani eliphelele lamanje, futhi njengoba ubukhulu be-weldment buncipha, izinga le-shunt nalo liyehla.

(2) Isimo sendawo yokushisela.Uma kukhona ama-oxides noma ukungcola ebusweni be-weldment, ukumelana nokuxhumana phakathi kwama-weldments amabili kuyanda, futhi okwamanje ngokusebenzisa indawo yokushisela kunciphisa, okungukuthi, izinga le-shunt liyakhula.I-workpiece ingaba pickled, sandblasted noma polished.

Izinyathelo Zokuphepha

(1) I-foot switch yomshini wokushisela kufanele ibe nesembozo esiqinile sokuvikela ukuvimbela ukusebenza ngengozi.

(2) Indawo okusetshenzwa kuyo kufanele ifakwe i-baffle ukuvimbela ukuchaphazeka kwezinhlansi ezisebenzayo.

(3) Abashiselayo kufanele bafake izibuko zokuzivikela eziyisicaba lapho beshisela.

(4) Indawo lapho umshini wokushisela ubekwe khona kufanele igcinwe yomile, futhi inhlabathi kufanele imbozwe ngamabhodi avimbela ukushibilika.

(5) Ngemva komsebenzi wokushisela, ugesi kufanele unqanyulwe, futhi inkinobho yamanzi okupholisa kufanele inwetshwe imizuzwana eyi-10 ngaphambi kokuvala.Uma izinga lokushisa liphansi, amanzi anqwabelene emgudwini wamanzi kufanele asuswe ukuze kuvinjelwe ukubanda.

Isikhathi sokuthumela: Jul-31-2023