-I-FLUX-

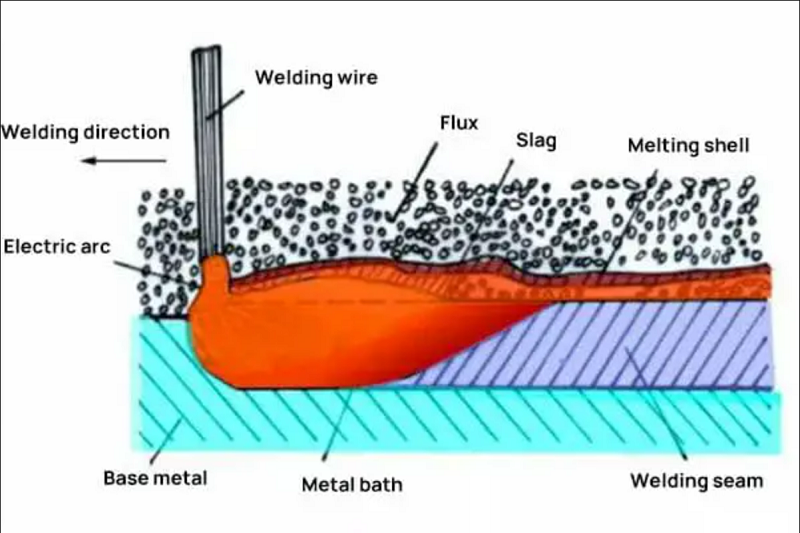

I-Fluxi-granular welding material.Ngesikhathi sokushisela, ingancibilika ukuze yakhe i-slag negesi, edlala indima yokuvikela kanye ne-metallurgical echibini elincibilikisiwe.

Okuhlanganisayo

I-Flux yakhiwe ngemabula, i-quartz, i-fluorite namanye ama-ores kanye ne-titanium dioxide, i-cellulose namanye amakhemikhali.I-Flux isetshenziselwa ikakhulukazi ukushisela i-arc engaphansi kwamanzi kanye nokushisela i-electroslag.Uma isetshenziselwa ukushisela zonke izinhlobo zensimbi nezinsimbi ezingezona ayoni, kufanele kube ukusetshenziswa okunengqondo nentambo yokushisela ehambisanayo ukuze uthole ukushisela okwanelisayo.

Ukwahlukanisa

Kunezindlela eziningi zokuhlukanisa zokuguquguquka, ngokuya ngokusetshenziswa, indlela yokukhiqiza, ukwakheka kwamakhemikhali, ukushisela kanye nezakhiwo ze-metallurgical zesigaba, kodwa futhi ngokuya nge-pH yokuguquguquka, ukuhlukaniswa kwe-flux granularity.Kungakhathaliseki ukuthi yiluphi uhlobo lwendlela yokuhlukanisa, ibonisa kuphela izici zokuguquguquka okuvela esicini esithile, ayikwazi ukufaka zonke izici zokuguquguquka.Izindlela zokuhlukanisa ezivame ukusetshenziswa yilezi:

1. Ukuguquguquka kokungathathi hlangothi

I-flux engathathi hlangothi ibhekisela ekushintsheni okungashintshi kakhulu ukwakheka kwamakhemikhali ensimbi ehlanganisiwe kanye nokwakheka kwamakhemikhali ocingo lokushisela ngemva kokushisela.I-flux engathathi hlangothi isetshenziselwa i-multi-pass welding, ikakhulukazi ukushisela isisekelo sensimbi enogqinsi olungaphezu kuka-25mm. I-flux engathathi hlangothi inezici ezilandelayo:

a.I-flux empeleni ayiqukethe i-SiO2, MnO, FeO namanye ama-oxide.

b.I-Flux ayinawo umphumela we-oxidation kunsimbi ye-weld ngokuyisisekelo.

c.Lapho kushiselwa isisekelo sensimbi ene-oxidation eqinile, kuzokhiqizwa ama-pores kanye nemifantu ye-weld.

2. Ukuguquguquka okusebenzayo

I-flux esebenzayo ibhekisela ekwengezweni kwenani elincane le-Mn, Si deoxidizer flux.Ingathuthukisa ukumelana ne-porosity kanye nokuqhekeka.I-flux esebenzayo inezici ezilandelayo:

a.Ngenxa ye-deoxidizer, uMn no-Si ensimbi encibilikisiwe bazoshintsha nge-arc voltage.Ukwanda kwe-Mn no-Si kuzokwandisa amandla ensimbi encibilikisiwe futhi kunciphise ukuqina komthelela.Ngakho-ke, i-arc voltage kufanele ilawulwe ngokuqinile lapho i-multi - pass welding.

b.I-flux esebenzayo inokumelana okuqinile kwe-porosity.

3. Ingxubevange

I-alloy flux yengeze izingxenye ze-alloy ezengeziwe zokuguqulwa kwezinto ze-alloying, iningi le-alloying flux liyi-sintered flux.I-alloy flux isetshenziselwa ikakhulukazi ukushisela insimbi ye-alloy ephansi kanye nokungaphezulu okungagugi.

4. Melt flux

I-Melt flux yizinto zokusetshenziswa zamaminerali ahlukahlukene axutshwe ngokuhambisana nesilinganiso esinikeziwe, ashise abe ngaphezu kwama-degree angu-1300, ancibilike futhi axutshwe ngokulinganayo, bese epholiswa emanzini ukuze afake i-granulate.Ngemuva kokumisa, ukugaya, ukuhlunga, ukusetshenziswa kokupakisha.

Umkhiqizo wokuncibilika kwasekhaya uvezwa ngokuthi “HJ”.Idijithi yokuqala ngemuva kwayo ikhombisa okuqukethwe kwe-MnO, idijithi yesibili ikhombisa okuqukethwe kwe-SiO2 ne-CaF2, kanti idijithi yesithathu ikhombisa izinhlobo ezahlukahlukene zohlobo olufanayo lokuguquguquka.

5. I-Sintering flux

Yomile ixutshwe ngokwengxenye enikeziwe yezithako, bese ingeza i-binder (ingilazi yamanzi) yokuxuba okumanzi, bese i-granulation, bese ithunyelwa esithandweni sokumisa ukuphulukiswa, ukomisa, futhi ekugcineni ifakwe cishe ngama-degree angu-500.

Uhlobo lwe-flux ye-sintered yasekhaya imelelwa yi-"SJ", idijithi yokuqala emva kwalokho imele uhlelo lwe-slag, futhi amadijithi wesibili nowesithathu amelela izinhlobo ezahlukene ze-slag system flux efanayo.

Isikhathi sokuthumela: May-04-2023