Isingeniso

Njengoba indikimba yemoto ingumthwali wezinye izingxenye zemoto, ubuchwepheshe bayo bokukhiqiza bunquma ngokuqondile ikhwalithi yokukhiqiza iyonke yemoto.I-Welding iyinqubo ebalulekile yokukhiqiza ohlelweni lokukhiqiza umzimba wezimoto.Njengamanje, ubuchwepheshe bokushisela obusetshenziselwa ukushisela umzimba wezimoto ikakhulukazi buhlanganisa ukushisela indawo yokumelana, ukushisela kwe-MIG, ukushisela kwe-MAG kanye ne-laser welding.

Ubuchwepheshe bokushisela nge-laser njengobuchwepheshe bokushisela obusezingeni eliphezulu be-optoelectromechanical, uma buqhathaniswa nobuchwepheshe bendabuko bokushisela umzimba wezimoto, bunobuhle bokuminyana kwamandla aphezulu, isivinini sokushisela okusheshayo, ukucindezeleka okuncane kwe-welding kanye nokuguqulwa, kanye nokuguquguquka okuhle.

Isakhiwo somzimba wemoto siyinkimbinkimbi, futhi izingxenye zawo ikakhulukazi zinezindonga ezincane futhi zigobile.Ukushisela umzimba wezimoto kubhekene nobunzima obuthile, njengokushintsha kwempahla yomzimba, ukushuba okuhlukene kwezingxenye zomzimba, indlela yokushisela ehlukahlukene kanye namafomu ahlangene.Ngaphezu kwalokho, ukushisela umzimba wezimoto kunezidingo eziphezulu zekhwalithi yokushisela nokusebenza kahle kwe-welding.

Ngokusekelwe kumingcele yenqubo yokushisela efanele, i-laser welding ingaqinisekisa amandla aphezulu okukhathala kanye nokuqina komthelela wezingxenye ezibalulekile zomzimba wemoto, ukuze kuqinisekiswe ikhwalithi yokushisela kanye nempilo yesevisi yomzimba wemoto.Ubuchwepheshe bokushisela nge-laser bungajwayelana namafomu ahlukene ahlangene, ubukhulu obuhlukahlukene kanye nezinhlobo ezahlukene zempahla yezingxenye zomzimba ezizenzakalelayo zokushisela, ukuze kuhlangatshezwane nezidingo eziguquguqukayo zokukhiqiza umzimba wezimoto.Ngakho-ke, ubuchwepheshe be-laser welding buyindlela yobuchwepheshe ebalulekile yokufeza ukuthuthukiswa kwekhwalithi ephezulu yemboni yezimoto.

Ubuchwepheshe be-laser welding bomzimba wezimoto

I-laser deep penetration welding technology yomzimba wezimoto

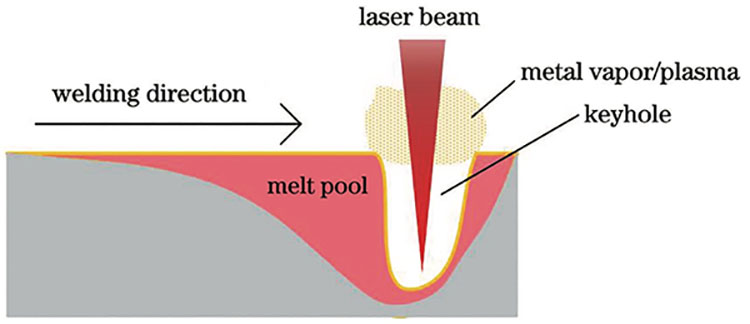

Isimiso se-laser deep penetration welding process (Figure 1) imi kanje: lapho ukuminyana kwamandla e-laser kufinyelela ezingeni elithile, ingaphezulu lezinto liyahwamuka, kwakheka imbobo yokhiye.Lapho umfutho womhwamuko wensimbi embobeni ufinyelela ibhalansi eguquguqukayo nengcindezi emile kanye nokushuba kwesimo soketshezi oluzungezile, i-laser ingakhanyiswa ifike phansi embobeni ngembobo kakhiye, futhi ngokuhamba kwe-laser beam, okuqhubekayo. weld kwakhiwa.Ngesikhathi senqubo yokufaka i-laser deep penetration welding, asikho isidingo sokwengeza i-auxiliary flux noma i-filler, futhi izinto zokwakha ze-workpiece zingahlanganiswa ndawonye.

I-FIG.1 Umdwebo we-Schematic wenqubo ye-laser yokungena ejulile ye-welding

I-weld etholwe nge-laser deep penetration welding ngokuvamile ibushelelezi futhi iqondile, kanti ukuwohloka kuncane, okusiza ekuthuthukiseni ukunemba kokukhiqiza komzimba wemoto.Amandla aphezulu we-weld aqinisekisa izinga lokushisela lomzimba wemoto.Ijubane lokushisela liyashesha, elisiza ekuthuthukiseni ukusebenza kahle kokukhiqizwa kwe-welding.

Enqubweni yokushisela umzimba wezimoto, ukusetshenziswa kwenqubo yokufaka i-laser deep penetration welding kunganciphisa kakhulu inani lezingxenye, isikhunta namathuluzi wokushisela, ngaleyo ndlela kunciphise isisindo somzimba nezindleko zokukhiqiza.Kodwa-ke, inqubo yokufaka i-laser deep penetration welding inokubekezelela okungalungile kwegebe lomhlangano wezingxenye ezishiselwe, futhi igebe lomhlangano lidinga ukulawulwa phakathi kuka-0.05 no-2 mm.Uma igebe lomhlangano likhulu kakhulu, amaphutha okushisela njengama-pores azokwenzeka.

Ucwaningo lwamanje lubonisa ukuthi i-weld enokwakheka okuhle kwendawo, ukukhubazeka okuncane kwangaphakathi kanye nezakhiwo ezinhle kakhulu zemishini ingatholakala ngokuthuthukisa imingcele yenqubo ye-laser deep penetration welding in the Welding of the material efanayo yemoto.Izakhiwo ezinhle kakhulu zemishini ye-weld zingahlangabezana nezidingo zezingxenye zokushisela zomzimba wemoto.Kodwa-ke, ekushiseleni umzimba wezimoto, ubuchwepheshe bokushisela obuhlukile be-laser deep penetration obumelwe i-aluminium alloy nensimbi abukavuthwa.Nakuba imithungo yokushisela esebenza kahle kakhulu ingatholwa ngokwengeza izendlalelo zoguquko, indlela yokuthonya yezinto ezihlukene zongqimba lwenguquko kungqimba lwe-IMC kanye nendlela yazo yokusebenza ku-weld microstructure ayicacile, futhi ucwaningo olwengeziwe luyadingeka.

Inqubo yokushisela i-automobile body laser wire filling

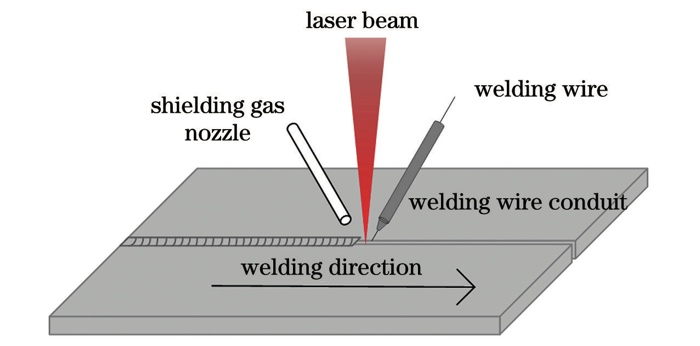

Umgomo wenqubo ye-laser filler wire welding inqubo kanje: ijoyinti elihlanganisiwe lakhiwa ngokugcwalisa ngaphambili ucingo oluthile lwe-welding ku-weld noma ukuphakela ucingo lwe-welding ngesikhathi esisodwa ngesikhathi senqubo ye-laser welding.Lokhu kulingana nokufaka izinto zocingo zokushisela cishe ezilinganayo echibini lokushisela phakathi ne-laser deep penetration welding.Umdwebo wohlelo lwenqubo yokushisela intambo ye-laser ukhonjiswe kuMfanekiso 2.

I-FIG.2 Umdwebo we-Schematic wenqubo ye-welding ye-laser yokugcwalisa ucingo

Uma kuqhathaniswa ne-laser deep penetration welding, i-laser wire filling welding inezinzuzo ezimbili ku-auto body welding: okokuqala, ingathuthukisa kakhulu ukubekezelelana kwegebe lomhlangano phakathi kwezingxenye zomzimba ze-auto okufanele zishiselwe, futhi ixazulule inkinga yokuthi i-laser deep penetration welding kudinga ukucaciswa kwe-groove kakhulu;Okwesibili, ukusatshalaliswa kwezicubu zendawo yokushisela kungathuthukiswa ngokusebenzisa izintambo zokushisela ezinokuqukethwe okuhlukile kokubunjwa, bese ukusebenza kwe-weld kungalawulwa.

Enqubweni yokukhiqiza umzimba wezimoto, inqubo yokufaka i-laser yokugcwalisa i-laser isetshenziswa kakhulu ukushisela i-aluminium alloy nezingxenye zensimbi zomzimba.Ikakhulukazi enqubweni yokushisela izingxenye ze-aluminium alloy yomzimba wemoto, ukungezwani okungaphezulu kwechibi elincibilikisiwe kuncane, okulula ukuholela ekuweni kwechibi elincibilikisiwe, futhi inqubo yokugcwalisa i-laser wire welding ingaxazulula kangcono inkinga yokuwa kwechibi elincibilikisiwe. ngokuncibilikisa intambo yokushisela.

Ubuchwepheshe be-Laser brazing bomzimba wemoto

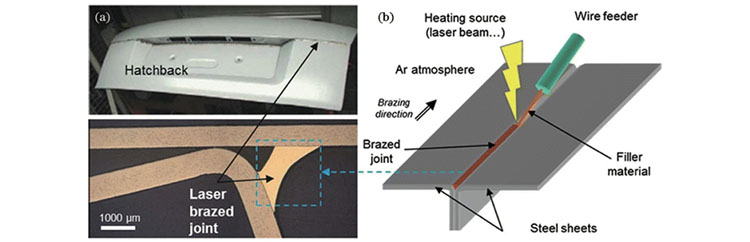

Umgomo wenqubo ye-laser brazing imi kanje: i-laser isetshenziswa njengomthombo wokushisa, i-laser beam ikhanyiswa ebusweni bocingo lwe-welding ngemva kokugxila, ucingo lokushisela luyancibilika, ucingo oluncibilikisiwe luwela futhi lugcwaliswe phakathi izingxenye ezizoshiselwa, kanye nemiphumela ye-metallurgical efana nokuncibilika nokusabalalisa kwenzeka phakathi kwensimbi yokugcwalisa kanye nendawo yokusebenza, ukuze ucezu lokusebenza luxhumeke.Ngokungafani nenqubo ye-laser yokugcwalisa i-welding, inqubo ye-laser brazing incibilikisa ucingo kuphela futhi ayincibiliki i-workpiece ukuze ishiselwe.I-laser brazing inozinzo oluhle lwe-welding, kodwa amandla aqinile we-weld aphansi.I-FIG.I-3 ikhombisa ukusetshenziswa kwenqubo ye-laser brazing ku-automobile boot boot lid welding.

I-FIG.3 Ukusebenzisa i-laser brazing emotweni: (a) i-laser welding ye-hood engemuva;(b) Umdwebo wohlelo lokubhula ngelaser

Enqubweni yokushisela umzimba wemoto, inqubo ye-laser brazing ikakhulukazi ukushisela izingxenye zomzimba ezinezidingo zamandla ahlangene aphansi, njengokushisela phakathi kwekhava engaphezulu nodonga oluseceleni lomzimba, ukushisela phakathi kwezingxenye ezingaphezulu nezingezansi zesiqu. ikhava, njll., iVolkswagen, Audi namanye amamodeli asezingeni eliphezulu ekhava ephezulu asebenzisa inqubo yokubhula ngelaser.

Ukukhubazeka okuyinhloko ku-laser brazing welding seam yomzimba wemoto kufaka phakathi ukuluma onqenqemeni, i-porosity, i-weld deformation, njll. Ukukhubazeka kungacindezelwa ngokusobala ngokulungisa amapharamitha wenqubo nokusebenzisa inqubo ye-laser brazing egxile kakhulu.

I-laser arc composite welding technology yomzimba wezimoto

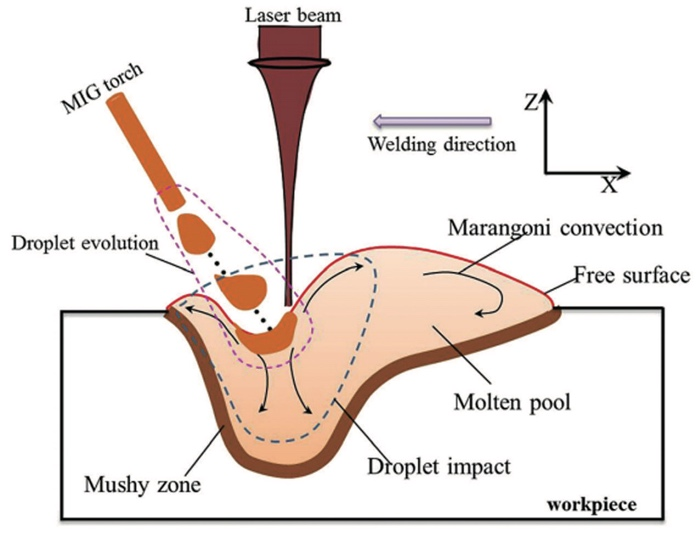

Isimiso senqubo yokushisela eyinhlanganisela ye-laser-arc simi kanje: ukusebenzisa imithombo emibili yokushisa ye-laser ne-arc ukuze isebenze phezu kwendawo yokusebenza ukuze ihlanganiswe ngesikhathi esifanayo, i-workpiece iyancibilika futhi iqiniswe ukuze yakhe i-weld.Umfanekiso wesi-4 ubonisa umdwebo wohlelo lwenqubo yokushisela eyinhlanganisela ye-laser-arc.

I-FIG.4 Umdwebo wohlelo lwenqubo yokushisela eyinhlanganisela ye-laser-arc

I-laser-arc composite welding inezinzuzo zakho kokubili i-laser welding kanye ne-arc welding: okokuqala, ngaphansi kwesenzo semithombo yokushisa ephindwe kabili, isivinini sokushisela siyathuthukiswa, okokufaka ukushisa kuncane, i-weld deformation incane, kanye nezici ze-laser welding. ziyagcinwa;Okwesibili, inekhono elingcono lokuvala ibhuloho kanye nokubekezelela okukhulu kwegebe lomhlangano;Okwesithathu, izinga lokuqiniswa kwechibi elincibilikisiwe lihamba kancane, elivumela ukuqeda izici zokushisela ezifana nezimbotshana nemifantu, kanye nokwenza ngcono ukwakheka nokusebenza kwendawo ethintekile ekushiseni.Okwesine, ngenxa yomphumela we-arc, ingakwazi ukushisela izinto ezibonakalayo ngokubonakala okuphezulu kanye ne-conductivity ephezulu ye-thermal, futhi ububanzi bezinto zokufaka isicelo bubanzi.

Enqubweni yokukhiqiza umzimba wezimoto, inqubo yokushisela eyinhlanganisela ye-laser-arc iwukushisela izingxenye zomzimba ze-aluminium ingxubevange kanye nezinsimbi ezingafani ze-aluminium-steel, futhi ukushiselwa kwenzelwe izingxenye ezinezikhala ezinkulu zokuhlanganisa, njengokushisela izingxenye zensimbi. umnyango wemoto, ngoba igebe lomhlangano livumela ukudlala ukusebenza kwebhuloho le-laser-arc composite welding.Ngaphezu kwalokho, ubuchwepheshe bokushisela obuhlanganisiwe be-laser-MIG arc buphinde busetshenziswe endaweni ephezulu eseceleni yomgodi womzimba we-Audi.

Enqubweni yokushisela umzimba wezimoto, i-laser-arc composite welding inenzuzo yokubekezelela igebe elikhulu kune-laser welding eyodwa, kodwa isikhundla esihlobene se-laser ne-arc, imingcele ye-laser welding, imingcele ye-arc nezinye izici kufanele kucatshangelwe ngokuphelele.Ukuziphatha kokushisa nokudluliswa kwenqwaba ekushiseleni kwe-laser-arc kuyinkimbinkimbi, ikakhulukazi indlela yokulawula amandla kanye nokuqina kwe-IMC nokulawulwa kwesakhiwo ekushiseleni okungafani okufanayo akukacaci, futhi ucwaningo olwengeziwe luyadingeka.

Ezinye izinqubo ze-automotive body laser welding

I-laser penetration welding, i-laser wire filling welding, i-laser brazing kanye ne-laser-arc composite welding nezinye izinqubo zokushisela kube yithiyori evuthiwe kanye nezicelo ezingokoqobo ezibanzi.Ngokuthuthuka kwezidingo zemboni yezimoto ekusebenzeni kahle kokushisela umzimba kanye nokwanda kwesidingo sokushisela izinto ezingafani ekwenziweni kwezimoto ezingasindi, ukushisela indawo ye-laser, ukushisela i-laser swing, i-multi-laser beam welding kanye ne-laser flight welding kunakiwe. ku.

Inqubo yokushisela indawo ye-laser

I-Laser spot welding ubuchwepheshe bokushisela nge-laser obuthuthukisiwe, obunobuhle bejubane lokushisela elisheshayo kanye nokunemba okuphezulu kwe-welding.Umgomo oyisisekelo wokushisela indawo ye-laser ukugxilisa isigxobo se-laser endaweni ethile engxenyeni ezoshiselwa, ukuze insimbi elapho incibilike khona manjalo, ngokulungisa ukuminyana kwe-laser ukuze kuzuzwe ukushiselwa kwe-thermal conduction noma umphumela we-fusion welding ojulile. , lapho i-laser beam iyeka ukusebenza, i-liquid metal igeleza futhi, iqiniswe ukuze yakhe ilunga.

Kunezinhlobo ezimbili eziyinhloko ze-laser spot welding: i-pulsed laser spot welding kanye ne-continuous laser spot welding.I-Pulsed laser spot welding laser beam peak energy iphezulu, kodwa isikhathi sokwenza sifushane, ngokuvamile sisetshenziselwa ingxubevange ye-magnesium, ingxubevange ye-aluminium nezinye izinsimbi zokushisela.Amandla amaphakathi we-laser beam ekushiseleleni indawo ye-laser aphezulu, isikhathi sesenzo se-laser side, futhi sisetshenziswa kakhulu ekushiseleni insimbi.

Mayelana nokushisela umzimba wezimoto, uma kuqhathaniswa ne-resistance spot welding, i-laser spot welding inezinzuzo zokungathinteki, indawo yokushisela indawo ingaklanywa ngokuzimela, njll., engahlangabezana nezidingo zokushisela izinga eliphezulu ngaphansi kwezikhala ezihlukene ze-lap. izinto zomzimba wemoto.

Inqubo yokushisela i-laser swing

I-Laser swing welding ubuchwepheshe obusha be-laser welding obuhlongozwe eminyakeni yamuva nje, obukhathazeke kakhulu.Isimiso salobu buchwepheshe siwukuthi: ngokuhlanganisa iqembu le-galvanometer ekhanda le-laser welding, i-laser beam iyashesha, ihlelekile futhi isendaweni encane, ukuze kuzuzwe umphumela we-laser beam ehamba phambili ngenkathi ivuselela.

Imizila yokushwiba eyinhloko enqubweni yokushisela i-laser ihlanganisa ukushwibeka okuphambene, ukushwibeka kwe-longitudinal, ukushwiba okuyisiyingi nokushwiba okungapheli.Inqubo ye-laser swing welding inezinzuzo ezibalulekile ekushiseleni komzimba wemoto.Ngaphansi kwesenzo sokushwibeka kwe-laser beam, isimo sokugeleza kwechibi elincibilikisiwe sishintshwa kakhulu.Ngakho-ke, inqubo ayikwazi kuphela ukuqeda isici esingaxutshiwe, ifinyelele ukucolisiswa okusanhlamvu futhi icindezele i-porosity ekushiseleni kwempahla efanayo yemoto.Ngaphezu kwalokho, kungase futhi kuthuthukise izinkinga ezinjengokungahlanganisi okwanele kwezinto ezisetshenziswayo kanye nezakhiwo ezingezinhle zemishini yama-welds ekushiseleni izinto ezihlukene zomzimba wemoto.

Inqubo yokushisela i-Multi-laser beam

Njengamanje, i-fiber optical laser ingahlukaniswa ibe yimishayo eminingi ye-laser nge-splitter module efakwe ekhanda lokushisela.I-Multi-laser beam welding ilingana nokusebenzisa imithombo eminingi yokushisa enqubweni yokushisela, ngokulungisa ukusatshalaliswa kwamandla kwe-beam, imishayo ehlukene ingafinyelela imisebenzi ehlukene, njengokuthi: i-beam ene-high density yamandla iyisigxobo esiyinhloko, esibhekene nokujula. ukungena kwe-welding;Ukuminyana kwamandla okuphansi kwe-beam kungahlanza futhi kushise kuqala ingaphezulu lezinto ezibonakalayo, futhi kwandise ukumuncwa kwamandla we-laser beam ngento.

Izinto zensimbi eziqinile eziqinile zisetshenziswa kakhulu emzimbeni wezimoto.Ubuchwepheshe be-multi-laser beam welding bungathuthukisa ukuziphatha kokuhwamuka komhwamuko we-zinc kanye nokuziphatha okuguquguqukayo kwechibi elincibilikisiwe kunqubo yokushisela yepuleti lensimbi elinamandla, kuthuthukise inkinga yokufafaza, futhi kuthuthukise amandla aqinile okushisela.

Inqubo yokushisela indiza ye-laser

Ubuchwepheshe bokushisela indiza ye-laser ubuchwepheshe obusha be-laser welding, obusebenza kahle kakhulu bokushisela futhi obungaklanywa ngokuzimela.Umgomo oyisisekelo wokushisela indiza nge-laser ukuthi uma i-laser beam isenzeka ezibukweni ze-X kanye ne-Y zesibuko sokuskena, i-Engeli yesibuko ilawulwa ukuhlela okuzimele ukuze kuzuzwe ukuchezuka kwe-laser beam kunoma iyiphi i-Engeli.

I-laser welding yendabuko yomzimba wezimoto incike kakhulu ekuhambeni okuvumelanayo kwekhanda le-laser welding eliqhutshwa irobhothi lokushisela ukuze kuzuzwe umphumela wokushisela.Kodwa-ke, ukusebenza kahle kokushisela komzimba wezimoto kunqunyelwe kakhulu ukunyakaza okuphindaphindayo kwerobhothi lokushisela ngenxa yenani elikhulu lama-welds nobude obude bokushisela.Ngokuphambene, i-laser flight welding idinga kuphela ukulungisa i-Angle yesibuko ukuze kuzuzwe ukushisela ngaphakathi kwebanga elithile.Ngakho-ke, ubuchwepheshe bokushisela indiza ye-laser bungathuthukisa kakhulu ukusebenza kahle kokushisela futhi bunamathemba abanzi wokufaka isicelo.

Isifinyezo kanye nethemba

Ngokuthuthuka kwemboni yezimoto, ubuchwepheshe bokushisela umzimba besikhathi esizayo buzoqhubeka buthuthuka ezicini ezimbili: inqubo yokushisela kanye nobuchwepheshe obukhaliphile.

Umzimba wezimoto, ikakhulukazi umzimba wezimoto zamandla amasha, uthuthuka ubheke kwesisindo esingasindi.Ama-alloys angasindi, izinto eziyinhlanganisela nezinto ezingafani zizosetshenziswa kabanzi emzimbeni wezimoto, inqubo evamile yokushisela i-laser inzima ukuhlangabezana nezidingo zayo zokushisela, ngakho-ke inqubo yokushisela yekhwalithi ephezulu nephumelelayo izoba umkhuba wokuthuthukiswa kwesikhathi esizayo.

Eminyakeni yamuva nje, izinqubo zokushisela i-laser ezivelayo, njenge-laser swing welding, i-multi-laser beam welding, i-laser flight welding, njll., beziwucwaningo lokuqala lwethiyori kanye nokuhlola inqubo ngokwekhwalithi yokushisela nokusebenza kahle kokushisela.Ngokuzayo, kuyadingeka ukuhlanganisa eduze inqubo ye-laser welding ekhulayo nezinto ezingasindi nezinto ezingafani zokushisela izigcawu zomzimba wemoto, kwenziwe ucwaningo olujulile ngokwakhiwa kwe-laser beam swing trajectory, indlela yokusebenza yamandla amaningi we-laser. kanye nokwenza ngcono ukusebenza kahle kwe-flight welding, kanye nokuhlola inqubo yokushisela umzimba wemoto engasindi ekhulile.

Ubuchwepheshe be-laser welding bomzimba wezimoto buhlanganiswe ngokujulile nobuchwepheshe obuhlakaniphile.Umbono wesikhathi sangempela wesimo sokushisela nge-laser somzimba wemoto kanye nokulawulwa kwempendulo yamapharamitha wenqubo kudlala indima ebalulekile kwikhwalithi yokushisela.Ubuchwepheshe bamanje be-laser welding obuhlakaniphile busetshenziselwa kakhulu ukuhlela umzila we-pre-welding kanye nokulandelela kanye nokuhlolwa kwekhwalithi yangemuva kokushisela.Ekhaya naphesheya, ucwaningo lokutholwa kwesici sokushisela kanye nokulawula okuguquguqukayo kwepharamitha kusesesigabeni sokuqala, futhi ubuchwepheshe bokulawula ipharamitha ye-laser welding ayikasetshenziswa ekukhiqizeni umzimba wezimoto.

Ngakho-ke, uma kubhekwa izici zokusetshenziswa kobuchwepheshe bokushisela nge-laser ohlelweni lokushisela umzimba wezimoto, uhlelo lokuzwa okuhlakaniphile lwe-laser welding olunama-multi-sensor athuthukile njengomongo kanye nohlelo lokulawula irobhothi lokushisela olunesivinini esikhulu futhi olunembayo kufanele lube. ithuthukiswe esikhathini esizayo ukuze kuqinisekiswe isikhathi sangempela kanye nokunemba kwazo zonke izici zobuchwepheshe be-laser welding ezihlakaniphile.Vula isixhumanisi "se-pre-welding trajectory planning - ipharamitha eguquguqukayo yokulawula ukutholwa kwekhwalithi yokushisela ku-inthanethi ngemva kokushisela" ukuze uqinisekise ukucutshungulwa kwekhwalithi ephezulu nokusebenza kahle.

Isikhathi sokuthumela: Oct-16-2023