Isidingo sensimbi emphakathini wanamuhla sikhula njalo.Empilweni yansuku zonke, izinto eziningi zenziwe ngensimbi, futhi izinsimbi eziningi azikwazi ukuphonswa ngesikhathi esisodwa.Ngakho-ke, kuyadingeka ukusebenzisa i-welding kagesi ye-welding.Indima ye-electrode ohlelweni lwe-welding kagesi ibaluleke kakhulu.

Induku yokushisela inamandla futhi iyancibilika ekushiseni okuphezulu ngesikhathi sokushisela i-arc, futhi igcwalisa amalunga omsebenzi wokushisela.Imvamisa, i-electrode ehambisanayo ikhethwa ngokuya ngezinto ze-welding workpiece.Induku yokushisela ingasetshenziselwa ukushisela uhlobo olufanayo lwensimbi noma ukushisela phakathi kwezinsimbi ezahlukene.

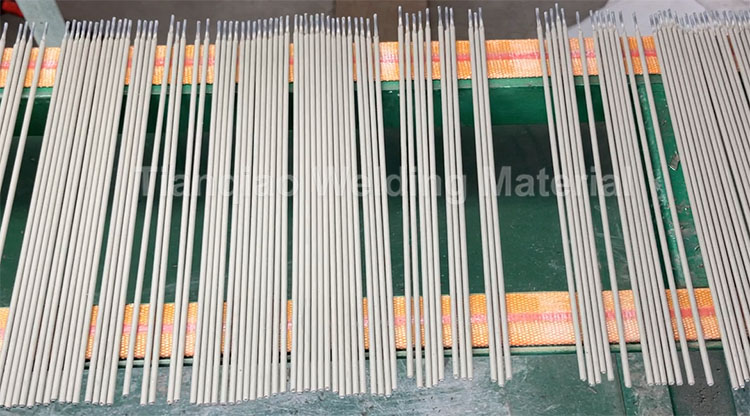

Ukwakhiwa kwe-Welding Electrode

Ingqikithi yensimbi yangaphakathi yenduku yokushisela kanye nokugqoka kwangaphandle kwakhiwa.I-welding core iyintambo yensimbi enobubanzi nobude obuthile.Umsebenzi oyinhloko we-welding core ukuqhuba okwamanje ukushisa nokuncibilika, nokugcwalisa nokuxhuma i-workpiece.

Izinto eziwumgogodla ezisetshenziselwa ukushisela zingahlukaniswa zibe yi-carbon steel, i-alloy steel nensimbi engagqwali.Kodwa-ke, ukuze kuhlangatshezwane nezidingo zokushisela, kunezidingo ezikhethekile zezinto ezibonakalayo nezensimbi ze-welding core, futhi kunemithetho eqinile mayelana nokuqukethwe kwezinye izakhi zensimbi.Ngoba ukwakheka kwensimbi ye-welding core kuzothinta ngqo ikhwalithi ye-weld.

Kuyoba khona ungqimba lwe-coating ngaphandle kwe-electrode, ebizwa ngokuthi i-flux coat.Ijazi le-Flux lidlala indima ebalulekile.Uma i-welding core kagesi isetshenziselwa ukushisela i-workpiece ngokuqondile, umoya nezinye izinto zizongena ensimbi encibilikisiwe ye-welding core kagesi, futhi ukusabela kwamakhemikhali kuzokwenzeka ensimbi encibilikisiwe ukuze kubangele ngokuqondile ukushisela.Izinkinga zekhwalithi ezinjengama-pores kanye nemifantu zizoba nomthelela ekuqineni kokushisela.Ijazi le-Flux eliqukethe izakhi ezikhethekile lizobola futhi lincibilike libe yigesi kanye ne-slag emazingeni okushisa aphezulu, okungavimbela ngokuphumelelayo umoya ukuthi ungangeni futhi uthuthukise izinga lokushisela.

Izithako zejazi le-flux zifaka: i-hydrochloric acid, i-fluoride, i-carbonate, i-oxide, i-organic matter, i-iron alloy nezinye izimpushana zamakhemikhali, njll., ezixutshwe ngokwesilinganiso esithile sefomula.Ukubunjwa kokugqoka kwezinhlobo ezahlukene ze-electrode coatings nakho kuhlukile.

Kunezinhlobo ezintathu ezijwayelekile, okuyi-ejenti ye-slag, i-ejenti ekhiqiza igesi, ne-deoxidizer.

I-ejenti ye-slag iyinhlanganisela engavikela insimbi encibilikisiwe ekungeneni komoya lapho i-electrode incibilika, ngaleyo ndlela ithuthukise ikhwalithi yokushisela.

I-ejenti ekhiqiza igesi ikakhulukazi yakhiwe isitashi nofulawa wezinkuni nezinye izinto, ezinezinga elithile lokunciphisa.

I-deoxidizer yakhiwe i-ferro-titanium ne-ferromanganese.Ngokuvamile, izinto ezinjalo zingathuthukisa ukumelana nokugqoka kanye nokumelana nokugqwala kwezinsimbi.

Ngaphezu kwalokho, kunezinye izinhlobo zokugqoka endaweni ye-electrode, futhi ukwakheka kanye nesilinganiso sohlobo ngalunye kuzohluka.

Inqubo yokukhiqiza ye-welding electrode

Inqubo yokukhiqiza yenduku yokushisela iwukwenza umgogodla wokushisela futhi ulungise ukugqoka ngokuvumelana nezidingo zokuklama zenduku yokushisela, futhi usebenzise ukunamathela ngokulinganayo kumgogodla wokushisela ukuze uhlangabezane nezidingo zokuklama zenduku ye-welding efanelekayo.

Okokuqala, ibha yensimbi egoqiwe ikhishwa ku-coiler, ukugqwala ebusweni bensimbi yensimbi kukhishwa emshinini, bese iqondiswa.Umshini usika ibha yensimbi ibe ubude be-electrode.

Okulandelayo, i-coating idinga ukulungiswa ebusweni be-electrode.Izinto ezihlukahlukene zokusetshenziswa kwe-coating zihlungwa ukuze zisuse ukungcola, bese zithululelwa emshinini ngokuvumelana nesilinganiso, futhi i-binder yengezwe ngesikhathi esifanayo.Zonke izinto zokusetshenziswa eziyimpuphu zixutshwe kahle ngokunyakaza komshini.

Faka impushana exutshwe esikhunjeni bese uyicindezela ibe isilinda esiyisilinda esinembobo eyisiyingi phakathi.

Faka imiphongolo eminingi ecindezelwe emshinini, faka ama-welding cores kahle embotsheni yokuphakela umshini, ama-welding cores angena emshinini asuka echwebeni lokuphakela umshini ngokushintshana, bese kuthi ama-wedling cores adlule phakathi komgqomo ngenxa yokukhishwa.Umshini usakaza ngokulinganayo impushana kumongo odlulayo ukuze ube ukunamathela.

Ngesikhathi senqubo yokumboza yenduku ye-welding, yonke ingqikithi yokuthungatha ihlanganiswe nesendlalelo sokumboza.Ukuze wenze i-electrode ibe lula ukuyibamba futhi iqhube ugesi, ikhanda nomsila we-electrode kudingeka kupholishwe kucolile ukuze kuvezwe umgogodla wokushisela.

Ngemuva kokuthi ukugqoka kusetshenziswe, ikhanda lokugaya kanye nenduku yokushisela ngemva kokugaya umsila kuzohlelwa ngokulinganayo kuhlaka lwensimbi bese kuthunyelwa kuhhavini ukuze zomiswe.

Ukuze ukwazi ukuhlukanisa kalula ukucaciswa kanye namamodeli we-electrode, kuyadingeka ukuphrinta ku-electrode.Lapho induku yokushisela ihamba ebhandeni lokuthutha, i-electrode ngayinye iphrinta i-roller yokuphrinta yerabha ebhandeni lokuthutha.

Ngemuva kokuthi imodeli yenduku yokushisela iphrintiwe, induku yokushisela ingahlanganiswa futhi ithengiswe ngemuva kokuphumelela ukuhlolwa.

Ama-electrode we-Tianqiao welding we-brand anokusebenza okuhle kakhulu, ikhwalithi ezinzile, ukubunjwa kokushisela okuhle, nokususwa okuhle kwe-slag, ikhono elihle lokumelana nokugqwala, i-Stomata nokuqhekeka, izinhlamvu zensimbi ezifakiwe ezinhle nezinzile.Izinto zokushisela zohlobo lwe-Tianqiao zihlangabezana nokwamukelwa ngemfudumalo kwamakhasimende ngenxa yekhwalithi enhle kakhulu, ukusebenza okuvelele kanye nentengo yokuncintisana.Chofoza laphaukuze ubuke okwengeziwe ngemikhiqizo yethu

Isikhathi sokuthumela: Sep-03-2021