Umthombo wamandla wokubhuqa kungaba ukushisa kokusabela kwamakhemikhali noma amandla okushisa angaqondile.Isebenzisa insimbi enephuzu lokuncibilika eliphansi kunaleyo yezinto okufanele zishiselwe njenge-solder.Ngemuva kokushisa, i-solder iyancibilika, futhi isenzo se-capillary sicindezela i-solder ibe yigebe phakathi kwezindawo zokuthintana zejoyinti ukuze imanzise ingaphezulu lensimbi ukuze ihlanganiswe ukuze isigaba se-liquid kanye nesigaba esiqinile sihlukaniswe.Ukwehlukanisa phakathi kwezigaba ukuze kwakhiwe ilunga eliqinile.Ngakho-ke, i-brazing iyindlela ye-solid-phase kanye ne-liquid-phase welding.

1. Izici kanye nokusetshenziswa kwe-brazing

I-Brazing isebenzisa i-alloy enephoyinti lokuncibilika eliphansi kunalelo lensimbi eyisisekelo njenge-solder.Uma ishiswa, i-solder iyancibilika futhi igcwale futhi ihlale esikhaleni esihlanganyelwe ngokumanzisa kanye nesenzo se-capillary, kuyilapho isisekelo sensimbi sisesimweni esiqinile, sincike ku-solder ewuketshezi kanye nesisekelo esiqinile Ukuxubana phakathi kwezinto kwakha ilunga eliqinile.I-Brazing inomthelela omncane ezintweni ezibonakalayo namakhemikhali esisekelo sensimbi, ingcindezi encane yokushisela kanye nokuguqulwa, ingakwazi ukushisela izinsimbi ezihlukene ezinomehluko omkhulu wezakhiwo, ingaqedela ama-welds amaningi ngesikhathi esisodwa, ukubukeka kokuhlangana kuhle futhi kuhlelekile, imishini ilula, kanye nokutshalwa kwezimali ukukhiqiza kuncane.Kodwa-ke, i-brazed joint inamandla aphansi kanye nokumelana nokushisa okubi.

Izicelo: Amathuluzi okusika i-Carbide, izingcezu zokubhoboza, amafreyimu ebhayisikili, abashintshi bokushisa, amapayipi kanye neziqukathi ezihlukahlukene, njll.;ekwakhiweni kwamagagasi e-microwave, amashubhu e-electron kanye namadivayisi e-vacuum kagesi, i-brazing iwukuphela kwendlela yokuxhumana engenzeka.

2.I-brazing metal kanye ne-flux

Insimbi yokugcwalisa i-brazing iyinsimbi yokugcwalisa eyakha ikhanda eligqamile, futhi ikhwalithi yekhanda lokubhoboza incike ensimbi yokugcwalisa insimbi ngezinga elikhulu.I-filler metal kufanele ibe nendawo encibilikayo efanelekile, ukumanzisa okuhle kanye nekhono lokubangela, ingasatshalaliswa ngesisekelo sensimbi, futhi kufanele ibe nezakhiwo ezithile zemishini kanye nezakhiwo zomzimba namakhemikhali ukuze kuhlangatshezwane nezidingo zokusebenza zejoyinti.Ngokwendawo encibilikayo ehlukene ye-brazing filler metal, i-brazing ingahlukaniswa ngezigaba ezimbili: i-soft brazing kanye ne-hard brazing.

(1) Ukubhuqa okuthambile.I-Brazing enendawo yokuncibilika engaphansi kuka-450 ° C ibizwa ngokuthi i-soft brazing, futhi insimbi yokugcwalisa evame ukusetshenziswa i-tin lead brazing, enokumanzisa okuhle nokuhamba kukagesi futhi isetshenziswa kakhulu emikhiqizweni ye-elekthronikhi, izinto zikagesi zezimoto nezingxenye zezimoto.Amandla elunga eliqinile ngokuvamile angu-60 ~ 140MPa.

(2) Ukubhuqa.I-Brazing enephuzu lokuncibilika elingaphezu kuka-450 ° C kubizwa ngokuthi i-brazing, futhi izinto ezivamile zokubrawuza izinto eziyisisekelo zethusi nezesiliva.I-joint ene-silver base filler metal inamandla aphezulu, ukuqhutshwa kukagesi kanye nokumelana nokugqwala, indawo yokuncibilika yensimbi yokugcwalisa iphansi, futhi inqubo yinhle, kepha intengo yensimbi yokugcwalisa iphezulu, futhi isetshenziswa kakhulu ukushisela. izingxenye ezinezidingo eziphakeme.I-Brazing isetshenziswa kakhulu ezintweni zokusebenza zensimbi nezethusi ezinamandla amakhulu, kanye namathuluzi okubraza.Amandla ahlangene ahlanganisiwe angu-200 ~ 490MPa,

Qaphela: Indawo yokuxhumana yesisekelo kufanele ihlanzeke kakhulu, ngakho-ke i-flux kufanele isetshenziswe.Indima ye-flux ukususa ukungcola kwe-oxide namafutha ebusweni bensimbi eyisisekelo kanye nensimbi yokugcwalisa, ukuvikela indawo yokuxhumana yensimbi yokugcwalisa kanye nesisekelo sensimbi kusuka ku-oxidation, futhi kwandise ukumanzi kanye ne-capillary fluidity yesigcwalisi. insimbi.Indawo yokuncibilika ye-flux kufanele ibe ngaphansi kunaleyo yensimbi yokugcwalisa, futhi ukugqwala kwensalela ye-flux kusisekelo sensimbi namajoyini kufanele kube kuncane.I-brazing flux evamile iyisisombululo se-rosin noma i-zinc chloride, futhi i-brazing flux evamile iyingxube ye-borax, i-boric acid ne-alkaline fluoride.

Ngokwemithombo ehlukene yokushisa noma izindlela zokushisisa i-brazing ingahlukaniswa ibe:i-flame brazing, i-induction brazing, ukushisa kwesithando somlilo, i-dip brazing, i-resistance brazing nokunye.Ngenxa yokuthi izinga lokushisa lokushisa liphansi kakhulu ngesikhathi sokubhula, linomthelela omncane ekusebenzeni kwezinto zokusebenza, futhi ukuguqulwa kokucindezeleka kwe-weldment nakho kuncane.Nokho, amandla elunga eliqinile ngokuvamile aphansi, futhi ukumelana nokushisa kubi.

Indlela yokushisisa i-Brazing:Cishe yonke imithombo yokushisisa ingasetshenziswa njengemithombo yokushisa ye-brazing, futhi ngokusho kwalokhu kubhula kuhlukaniswa.

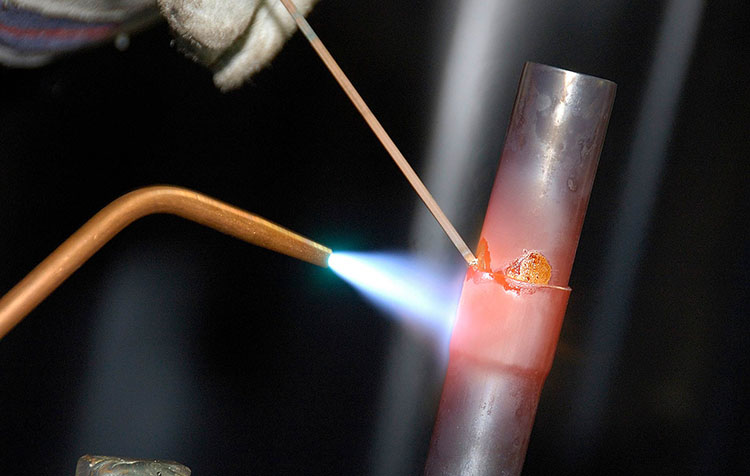

I-flame brazing:ukufudumeza ngelangabi legesi, okusetshenziselwa i-carbon steel, insimbi engagqwali, i-carbide, insimbi ecijile, ithusi ne-alloys yethusi, i-aluminium ne-aluminium alloy brazing.

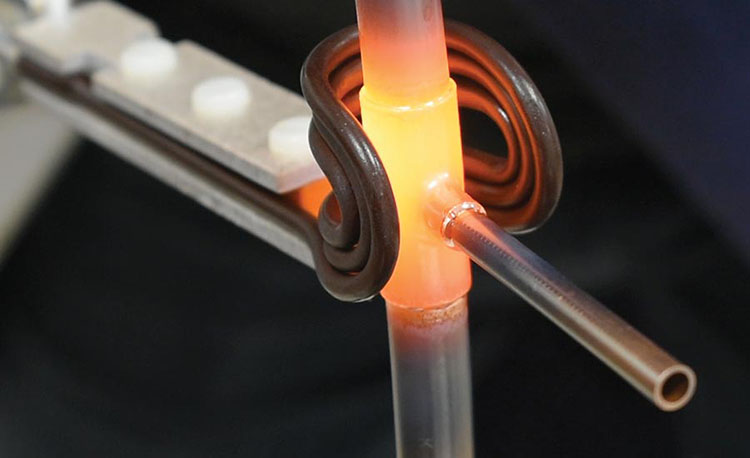

I-Induction brazing:Ukusetshenziswa kwezindawo kazibuthe ezishintshayo ukuze kukhiqizwe amandla akhona engxenyeni ye-welding yokushisa yokumelana nokushisa, ukuze kube nokuma okulinganayo kwe-welding, ikakhulukazi ukubrashiswa kwe-pipe shaft.

I-Dip brazing:ingxenye yokushisela iyingxenye noma icwiliswe ngokuphelele engxubeni kasawoti encibilikisiwe noma i-solder incibilike, ithembele ekushiseni kwalezi zindaba eziwuketshezi ukuze kuzuzwe inqubo yokubhoboza, ebonakala ngokushisa okusheshayo, ukushisa okufanayo, ukuguqulwa okuncane kwengxenye ye-welding.

Ukushisa kwesithando somlilo:Ama-welds ashiswa yisithando somlilo sokumelana, esingavikela ama-welds ngokuhlanza noma ngokusebenzisa amagesi anciphisa noma angenayo.

Ngaphezu kwalokho, kukhona i-soldering iron brazing, resistance brazing, diffusion brazing, infrared brazing, reaction brazing, electron beam brazing, laser brazing, njll.

I-Brazing ingasetshenziselwa ukushisela i-carbon steel, insimbi engagqwali, i-superalloy, i-aluminium, ithusi nezinye izinto zensimbi, futhi ingaxhuma izinsimbi ezingafani, izinsimbi nezingezona izinsimbi.Ifanele amajoyinti e-welding anomthwalo omncane noma ukusebenza ekamelweni lokushisa, ikakhulukazi efanelekile ngokunemba, ama-welds ama-multi-brazed ayinkimbinkimbi futhi ayinkimbinkimbi.

Isikhathi sokuthumela: Jul-06-2023