Q1: Iyini impahla yokushisela?Yini ongayifaka?

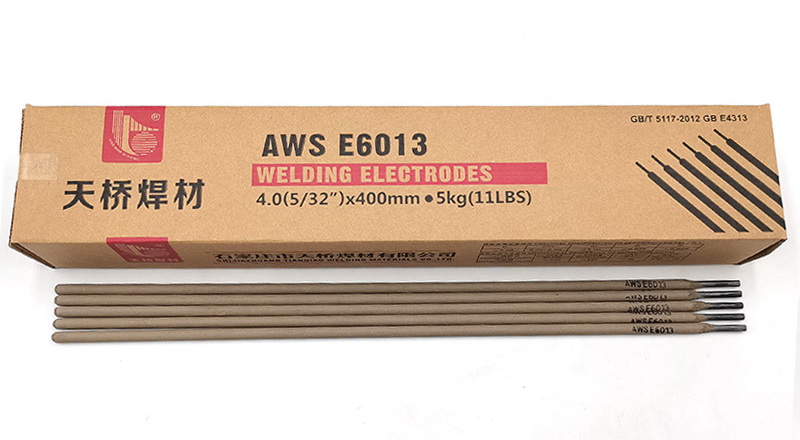

Impendulo: Izinto zokushisela zihlanganisa izinduku zokushisela, izintambo zokushisela, ama-fluxes, amagesi, ama-electrode, ama-gaskets, njll.

Q2: Iyini i-acid electrode?

Impendulo: Ukumbozwa kwe-acid electrode kuqukethe inani elikhulu lama-acid oxides afana ne-SiO2, i-TiO2 kanye nenani elithile le-carbonate, futhi i-alkalinity ye-slag ingaphansi kwe-1. Ama-electrodes e-Titanium, i-calcium titanium electrode, i-ilmenite electrode ne-iron oxide ama-electrode wonke ama-electrode ane-asidi.

Q3: Iyini i-alkaline electrode?

Impendulo: I-alkaline electrode coating iqukethe inani elikhulu lezinto zokwakha i-alkaline slag njengemabula, i-fluorite, njll., futhi iqukethe inani elithile le-deoxidizer kanye ne-alloying agent.Ama-electrode ohlobo oluphansi lwe-hydrogen angama-alkaline electrode.

Q4: Iyini i-cellulose electrode?

Impendulo: I-electrode coating inokuqukethwe okuphezulu kwe-cellulose kanye ne-arc ezinzile.Ibola futhi ikhiqize inani elikhulu legesi ukuvikela insimbi yokushisela ngesikhathi sokushisela.Lolu hlobo lwe-electrode lukhiqiza i-slag encane kakhulu futhi kulula ukuyisusa.Ibizwa nangokuthi i-electrode ye-welding eqondile eyehlayo.Ingashiswa kuzo zonke izikhundla, futhi i-welding eqondile ingashiselwa phansi.

Q5: Kungani i-electrode kufanele yomiswe ngokuqinile ngaphambi kokushiswa?

Izinduku zokushisela zivame ukuwohloka ukusebenza kwenqubo ngenxa yokumuncwa komswakama, okuholela ku-arc engazinzile, ukwanda kwe-spatter, futhi kulula ukukhiqiza ama-pores, imifantu nokunye ukukhubazeka.Ngakho-ke, induku yokushisela kufanele yomiswe ngokuqinile ngaphambi kokusetshenziswa.Ngokuvamile, izinga lokushisa lokumisa le-acid electrode liyi-150-200 ℃, futhi isikhathi yihora elingu-1;izinga lokushisa lokumisa le-alkaline electrode lingu-350-400℃, isikhathi amahora angu-1-2, futhi yomiswa futhi ifakwe ku-incubator ku-100-150℃ Ngaphakathi, yithathe njengoba uhamba.

Q6: Iyini i-welding wire?

Impendulo: Lucingo lwensimbi olusetshenziswa njengensimbi yokugcwalisa ngesikhathi sokushisela futhi lusetshenziselwa ukuqhuba ugesi ngesikhathi esifanayo okuthiwa i-welding wire.Kunezinhlobo ezimbili: intambo eqinile kanye ne-flux-coreed wire.Imodeli yentambo yokushisela eqinile evame ukusetshenziswa: (Izinga le-GB-kazwelonke laseShayina) ER50-6 (ikilasi: H08Mn2SiA).(AWS-American Standard) ER70-6.

Q7: Iyini i-flux cored welding wire?

Impendulo: Uhlobo lwezintambo zokushisela ezenziwe ngezinsimbi ezincane ezigoqwe zibe amapayipi ensimbi ayindilinga futhi zigcwaliswe ukwakheka okuthile kwempushana.

Q8: Kungani i-flux cored wire ivikelwe igesi ye-carbon dioxide?

Impendulo: Kunezinhlobo ezine zocingo lokushisela olune-flux-cored: i-acidic flux-cored gas shielded welding wire (uhlobo lwe-titanium), i-alkaline flux-cored gas shielded wire (uhlobo lwe-titanium calcium), i-metal powder uhlobo lwe-flux-coreed gas shielded welding wire. kanye ne-flux-cored self-shielded welding wire.I-titanium yasekhaya yohlobo lwe-flux-coreed gas shielded welding wire ngokuvamile ivikelwa igesi ye-CO2;ezinye izintambo zokushisela ezinama-flux-cored zivikelwe igesi exubile (sicela ubhekisele ekucacisweni kwentambo ene-flux-cored).Ukusabela kwe-metallurgical kwefomula ngayinye ye-gas slag kuhlukile, sicela ungasebenzisi igesi yokuvikela engalungile.I-Flux-cored welding wire gas slag isivikelo esihlanganisiwe, ukwakheka okuhle komthungo we-welding, izakhiwo eziphelele zemishini.

Q9: Kungani kunezidingo zobuchwepheshe zokuhlanzeka kwegesi ye-carbon dioxide?

Impendulo: Ngokuvamile, igesi ye-CO2 iwumkhiqizo wokukhiqizwa kwamakhemikhali, ngokuhlanzeka okungaba ngu-99.6% kuphela.Iqukethe imikhondo yokungcola kanye nomswakama, okuzoletha ukukhubazeka okufana nama-pores ekushiseni.Ngemikhiqizo ebalulekile yokushisela, igesi enobumsulwa be-CO2 ≥99.8% kufanele ikhethwe, ibe nezimbotshana ezincane ku-weld, okuqukethwe kwe-hydrogen ephansi, nokumelana nokuqhekeka okuhle.

Q10: Kungani kunezidingo eziphakeme zobuchwepheshe zokuhlanzeka kwe-argon?

Impendulo: Njengamanje kunezinhlobo ezintathu ze-argon emakethe: i-argon ecacile (ukuhlanzeka okuzungeze i-99.6%), i-argon ehlanzekile (ubumsulwa obuzungeze i-99.9%), ne-argon ephezulu (ubumsulwa 99.99%).Amabili okuqala angashiselwa ku-carbon steel nensimbi engagqwali.I-argon ehlanzekile kakhulu kufanele isetshenziselwe ukushisela izinsimbi ezingezona ayoni njenge-aluminium ne-aluminium alloys, i-titanium ne-titanium alloys;ukugwema i-oxidation ye-weld kanye nendawo ethintekile ekushiseni, ukwakheka kwe-weld okusezingeni eliphezulu nokuhle akutholakali.

Isikhathi sokuthumela: Jun-23-2021