Ukucindezeleka kwe-welding residual kubangelwa ukushisa okungalingani kokusatshalaliswa kwe-weldment okubangelwa ukushisela, ukunwetshwa kokushisa kanye nokunciphisa insimbi ye-weld, njll.

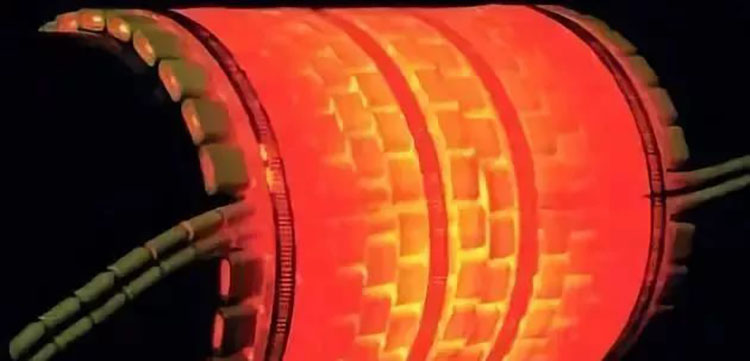

Indlela evame kakhulu yokuqeda ukucindezeleka okusalayo ukushisa okuphezulu kokushisa, okungukuthi, ukushisa i-weldment ekushiseni okuthile nokuyibamba isikhathi esithile esithandweni sokushisa ukushisa, nokusebenzisa ukunciphisa umkhawulo wesivuno sezinto ezibonakalayo. ekushiseni okuphezulu ukuze kubangele ukugeleza kwepulasitiki ezindaweni ezinokucindezeleka okukhulu kwangaphakathi.I-deformation ye-elastic iyancipha kancane kancane, futhi i-deformation yepulasitiki ikhula kancane kancane ukunciphisa ingcindezi.

1.Ukukhetha indlela yokwelapha ukushisa

Umthelela wokwelashwa kokushisa kwangemva kokushisela emandleni aqinile kanye nomkhawulo wokukhasa wensimbi uhlobene nezinga lokushisa lokwelapha ukushisa kanye nesikhathi sokubamba.Umthelela wokwelashwa kokushisa kwe-post-weld ekuqineni komthelela wensimbi ye-weld uyahlukahluka ngezinhlobo zensimbi ezihlukene.

Ukwelashwa kokushisa kwangemuva kwe-weld ngokuvamile kusebenzisa izinga lokushisa elilodwa eliphezulu noma ukujwayela kanye nezinga lokushisa eliphezulu.Ukuze kuhlanganiswe ama-welding wegesi, i-normalization kanye nokushisa okuphezulu kokushisa kuyamukelwa.Lokhu kungenxa yokuthi izinhlamvu ze-gas welding seam kanye nendawo ethinteke ukushisa ziqinile, futhi okusanhlamvu kudinga ukucwengwa, ngakho-ke ukwelashwa okujwayelekile kuyamukelwa.

Kodwa-ke, ukujwayela okukodwa akukwazi ukuqeda ukucindezeleka okusele, ngakho ukushisa okuphezulu kuyadingeka ukuze kuqedwe ukucindezeleka.Ukushisa okukodwa okuphakathi nendawo kulungele kuphela ukuhlanganiswa nokushiselwa kweziqukathi ezinkulu zensimbi ezinekhabhoni ephansi eziqoqwe esizeni, futhi inhloso yakhona ukufeza ukuqedwa kwengxenye yengcindezi eyinsalela kanye ne-dehydrogenation.

Ezimweni eziningi, ukushisa okukodwa okuphezulu kokushisa kusetshenziswa.Ukushisa nokupholisa ukwelashwa kokushisa akufanele kusheshe, futhi izindonga zangaphakathi nangaphandle kufanele zifane.

2.Izindlela zokwelapha ukushisa ezisetshenziswa ezitsheni zokucindezela

Kunezinhlobo ezimbili zezindlela zokwelapha ukushisa kwemikhumbi yokucindezela: enye iwukwelapha ukushisa ukuze kuthuthukiswe izakhiwo zemishini;enye i-post-weld heat treatment (PWHT).Uma sikhuluma kabanzi, ukwelashwa kokushisa kwangemva kwe-weld kuyindlela yokushisa endaweni eshiselwe noma izingxenye ezishiselwe ngemuva kokuthi ucezu lokusebenzela lushiselwe.

Okuqukethwe okuqondile kufaka phakathi ukuncishiswa kwengcindezi, ukuvala isifuba ngokuphelele, isixazululo esiqinile, ukujwayelekile, ukujwayelekile kanye nokushisa, ukufudumala, ukukhululeka kwengcindezi yezinga lokushisa eliphansi, ukwelashwa kokushisa kwezulu, njll.

Ngomqondo omncane, ukwelashwa kokushisa kwe-post-weld kubhekisela kuphela ekunciphiseni ingcindezi, okungukuthi, ukuze kuthuthukiswe ukusebenza kwendawo yokushisela futhi kuqedwe imiphumela eyingozi njengokushisela ingcindezi eyinsalela, ukuze kushise ngendlela efanayo futhi ngokugcwele indawo yokushisela. kanye nezingxenye ezihlobene ngezansi kwesigaba sensimbi soshintsho 2 iphuzu lokushisa , bese kuba inqubo yokupholisa iyunifomu.Ezimweni eziningi ukwelashwa kokushisa kwe-postweld okuxoxwe ngakho kuwukwelashwa kokushisa kokucindezeleka kwe-postweld.

3.Inhloso yokwelashwa kokushisa kwe-post weld

(1).Relax welding residual ingcindezi.

(2).Zinzisa ukuma nosayizi wesakhiwo futhi unciphise ukuhlanekezela.

(3).Thuthukisa ukusebenza kwesisekelo sensimbi namajoyinti ashiselwe, okuhlanganisa:

a.Thuthukisa ipulasitiki yensimbi yokushisela.

b.Yehlisa ubulukhuni bendawo ethinteke ukushisa.

c.Thuthukisa ukuqina kokuphuka.

d.Thuthukisa amandla okukhathala.

e.Buyisela noma wandise amandla okukhiqiza ancishisiwe ekubumbeni okubandayo.

(4).Thuthukisa ikhono lokumelana nokugqwala kwengcindezi.

(5).Ukukhulula ngokuqhubekayo amagesi ayingozi ensimbi yokushisela, ikakhulukazi i-hydrogen, ukuvimbela ukwenzeka kokuqhekeka okubambezelekile.

4.Ukwahlulelwa kwesidingo se-PWHT

Kungakhathaliseki ukuthi ukwelashwa kokushisa kwe-post-weld kuyadingeka yini emkhunjini wokucindezela kufanele kucaciswe ngokucacile ekwakhiweni, okudingwa yikhodi yamanje yokuklama umkhumbi wokucindezela.

Ngemikhumbi yokucindezela ehlanganisiwe, kukhona ukucindezeleka okukhulu okusalayo endaweni yokushisela, kanye nemiphumela emibi yokucindezeleka okusalayo.Kuboniswa kuphela ngaphansi kwezimo ezithile.Lapho ukucindezeleka okusalayo kuhlangana ne-hydrogen ekushiseleni, kuzokhuthaza ukuqina kwendawo ethinteke ukushisa, okuholela ekukhiqizeni imifantu ebandayo kanye nemifantu ebambezelekile.

Lapho ingcindezi emile esele ku-weld noma ingcindezi yomthwalo oguquguqukayo ekusebenzeni komthwalo ihlanganiswa nesenzo sokugqwala saphakathi nendawo, kungase kubangele ukugqwala kwe-crack, okuyilokho okubizwa ngokuthi ukugqwala kokucindezeleka.Ingcindezi yokushisela eyinsalela kanye nokuqina kwensimbi okuyisisekelo okubangelwa ukushisela kuyizici ezibalulekile zokuqhekeka kokugqwala kwengcindezi.

Imiphumela yocwaningo ibonisa ukuthi umthelela oyinhloko wokuguqulwa nokucindezeleka okusalayo ezintweni zensimbi ukwenza insimbi ishintshe isuka ekugqwaleni okufanayo iye ekugqwaleni kwendawo, okungukuthi, ukugqwala kwe-intergranular noma i-transgranular.Kunjalo, kokubili ukugqwala kokugqwala kanye nokugqwala kwe-intergranular kwezinsimbi kwenzeka kumidiya enezici ezithile zaleyo nsimbi.

Ebukhoneni bengcindezi eyinsalela, ihlukile ngokuya ngokwakheka, ukugxila kanye nezinga lokushisa lendawo ebolayo, kanye nomehluko ekubunjweni, ukwakheka, isimo esingaphezulu, isimo sokucindezeleka, njll. kwesisekelo sensimbi kanye nendawo yokushisela. , ukuze ukugqwala Imvelo yomonakalo ingashintsha.

5.Ukucutshungulwa komphumela ophelele we-PWHT

Ukwelashwa kokushisa kwe-post-weld akuzuzisi ngokuphelele.Ngokuvamile, ukwelashwa kokushisa kwangemuva kwe-weld kunenzuzo ekudambiseni ingcindezi esele, futhi kwenziwa kuphela lapho kunezidingo eziqinile zokugqwala kwengcindezi.Kodwa-ke, ukuhlolwa kokuqina komthelela kwesifanekiso kubonisa ukuthi ukwelashwa kokushisa kwangemva kokushisela akulungile kukuqina kwensimbi efakiwe kanye nendawo ethinteke kakhulu ekushiseni, futhi ngezinye izikhathi ukuqhekeka kwe-intergranular kungase kwenzeke phakathi kohla lokusanhlamvu oluqinile lokushisa kwe-weld- indawo ethintekile.

Ngaphezu kwalokho, i-PWHT incike ekwehlisweni kwamandla wezinto ezibonakalayo ezingeni lokushisa eliphezulu ukuze kuzuzwe ukukhululeka kwengcindezi.Ngakho-ke, ngesikhathi se-PWHT, isakhiwo singase silahlekelwe ukuqina.Ngezakhiwo ezisebenzisa i-PWHT iyonke noma ingxenye, ukushisela ezingeni lokushisa eliphezulu kufanele kucatshangelwe ngaphambi kokwelashwa kokushisa.amandla okusekela.

Ngakho-ke, uma kucatshangelwa ukuthi kufanele kwenziwe yini ukwelashwa kokushisa kwangemva kwe-weld, izinzuzo kanye nokubi kokwelashwa kokushisa kufanele kuqhathaniswe ngokuphelele.Ngokombono wokusebenza kwesakhiwo, kukhona uhlangothi olulodwa lokuthuthukisa ukusebenza, kanti olunye uhlangothi lokunciphisa ukusebenza.Isinqumo esiphusile kufanele senziwe ngesisekelo sokucutshungulwa okuphelele kwalezi zici ezimbili.

Isikhathi sokuthumela: Jun-20-2023