Ngokuthuthuka okusheshayo kwemboni ye-petrochemical, izinto zensimbi engagqwali ziye zasetshenziswa kabanzi, okubuye kwabeka izidingo eziphakeme zokushiselwa kwamapayipi namapuleti.Indlela yangaphambilini yensimbi engenasici ye-arc welding primer isuswe kancane kancane, futhi i-argon arc welding isetshenziselwa ukushisela i-primer.

I-Argon arc welding primer ihlanzekile futhi iyashesha kune-arc welding primer.Ngesikhathi esifanayo, kunezinkinga ezithile.

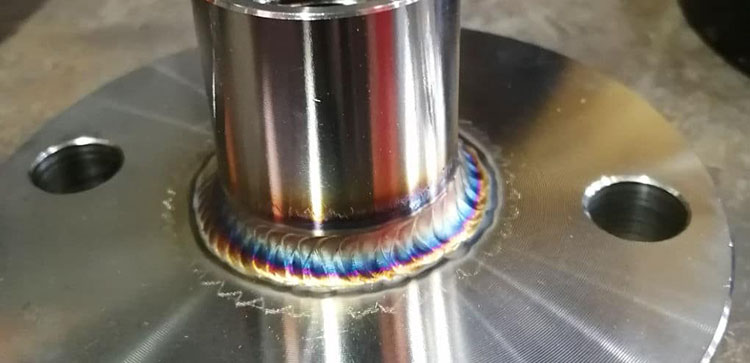

Ngesikhathi senqubo yokushisela, njengoba ngemuva kwesisekelo sensimbi engagqwali ye-argon arc welding kalula i-oxidized futhi ibangela ukukhubazeka, izinyathelo zokuvikela emuva kufanele zithathwe ukuze kuqinisekiswe izakhiwo zemishini kanye nokumelana nokugqwala kwe-weld.Ngakho-ke, ukuvikela okusebenzayo kufanele kuthathwe lapho kushiselwa insimbi engagqwali.

Namuhla sethula izindlela ezimbalwa ezivame ukusetshenziswa zensimbi engagqwali zokuvikela emuva:

01

Back Argon Protection Method

Amagesi avikelayo asetshenziswa ngokuvamile angahlukaniswa abe ukuvikelwa kwegesi ye-argon elula kanye nokuvikelwa kwegesi okuxubile.Ingxenye ethile yegesi exubile ye-argon-nitrogen ilungele ukushisela insimbi engagqwali ye-austenitic.Amanye amagesi angasebenzi awasetshenziswa ngenxa yezindleko zawo eziphakeme.

Ukuvikelwa kwendlela yokugcwalisa i-Argon kuyindlela evamile yokuvikela iqolo, enezici zokuvikela umhlane okungcono, okulula ukuzazi, ukuhlanzeka okuphezulu, nezinga eliphezulu lokuphasa.Ihlukaniswe ngendlela yokuvikela i-argon yokugcwalisa ikhava yokuvikela, indlela yokuvikela yokugcwalisa i-argon yendawo, ukugcwaliswa okuqondile kwe-welding joint, indlela yokuvikela i-argon welding, njll.

1. Ikhava yokuzivikela egcwele indlela yokuvikela i-argon

Le ndlela ivame ukusetshenziswa ekushiseleni insimbi engagqwali yamapuleti namapayipi anobubanzi obukhulu.Isembozo sokuzivikela sixhunywe kwipayipi yensimbi kanye ne-argon gas hose.I-argon gas valve ivuliwe ukugcwalisa ikhava yokuzivikela nge-argon gas.

Kudingeka omunye umuntu ukuthi abambe ipayipi lensimbi njengesibambo ukuze ikhava eyisivikelo ishelele echibini elincibilikisiwe elingemuva ngokuvumelanisa nokushisela kwangaphandle kwepuleti noma ipayipi.

Ngale ndlela, uhlangothi olungemuva luvikelwe ngokuphumelelayo, futhi ukuvikelwa kugxilile.I-argon gas ayidingi ukuvulwa kakhulu, futhi igesi ye-argon ichithwa kancane.

2. Ukuvikelwa kokugcwalisa i-argon yendawo

Kulula ukusebenzisa ukuvikeleka kwendawo kumapayipi anendawo encane yendawo kanye nobukhulu obufushane.

Indlela: Vala inhlanganisela yokushisela yepayipi ngeteyiphu (ukuvimbela ukuvuza komoya).Vala amaphethelo womabili wepayipi ngesipontshi, irabha, igobolondo lephepha, njll. Faka ipayipi le-argon ukusuka komunye umkhawulo bese uligcwalisa nge-argon.Omunye umkhawulo wepayipi uvalwe kangcono.Gcoba umgodi omncane (asikho isidingo sesipontshi), okuzokwenza kube lula ukuhlangana kokugcina kwe-welding futhi ngeke kubangele amazinyo ngenxa yokucindezela okukhulu kwangaphakathi.

Ngesikhathi sokushisela, ukuze kuvinjelwe inani elikhulu legesi ye-argon ekukhishweni kwe-weld seam, i-tape yokuvala uphawu kufanele ikhishwe futhi ifakwe ezigabeni, ezinganciphisa ukulahlekelwa okwengeziwe kwegesi ye-argon futhi ivikele ngempumelelo i-weld seam.Izici ziyamoshwa, ukushaja kwe-argon kuhamba kancane, izindleko ziphezulu kakhulu, njll.

3 .Indlela yokuvikela yokugcwalisa i-argon eqondile yejoyinti le-welding

Emapayipini amade kakhulu futhi anobubanzi obuthe ukukhudlwana, ukugcwaliswa kwe-argon yendawo kumosha kakhulu, ikhwalithi ayikwazi ukuqinisekiswa, futhi izindleko zephrojekthi ziphezulu kakhulu.Ukuze ulondoloze izindleko, indlela yokugcwalisa i-argon eqondile ekuhlanganyeleni okushiselwe ingasetshenziswa.

Indlela yokwenza amapulaki ezinhlangothini zombili ze-weld seam

Gcoba isipontshi sibe yipulaki enobubanzi obuthe xaxa bepayipi bese uxhuma izingcezu ezimbili zesipontshi ngocingo ebangeni elingama-300-400mm ukuze wenze ipulaki ekabili.Ingxenye eyodwa yepulaki ixhunywe ocezwini olude lwentambo yensimbi.

Uma kuhambisana, beka amapulaki ku-150-200mm ezinhlangothini zombili zokushisela ukuze ashiselwe.Intambo yensimbi ende ekugcineni kufanele ibe yinde kunobude bepayipi kwelinye icala le-weld futhi iveze ukuphela kwepayipi.Umkhawulo owodwa wepayipi elincane lensimbi kufanele ubekwe phansi futhi omunye umkhawulo kufanele uxhunywe ku-hose ye-argon.Faka ukuphela okuyisicaba ku-weld eqondisiwe bese uyigcwalisa nge-argon.Isiqondiso esingcono kakhulu sokufaka siyingxenye ephezulu, ukuze ngaphambi kokuhlangana kokugcina kwe-weld engezansi, ithubhu encane ingakhishwa futhi ihlanganiswe yigesi esele epayipini.Ngemva kokushisela, sebenzisa ucingo ukuze ukhiphe ipulaki.

Indlela yokuvikela iphepha elincibilikayo emanzini

Ngaphambi kokuhlanganisa, namathisela iphepha elincibilikayo emanzini ku-150-200mm ezinhlangothini zombili zejoyinti lokushisela njengophawu.Ngemva kokuqondisa, sebenzisa indlela efanayo yokushisela inflatable njengepulaki lesipontshi.Lapho ipayipi lihlolelwa umfutho we-hydraulic, iphepha elincibilikayo emanzini lizoncibilika futhi likhishwe ngamanzi.

4. Isahlulelo sokuvikela igesi ye-Argon

Umphumela wokuvikela we-argon gas ungahlulelwa ngokusho kombala we-weld yangaphakathi, ukuze opharetha akwazi ukulungisa igesi ye-argon ngokusho kombala ukuze afinyelele umphumela wokuvikela ongcono kakhulu.Imibala imhlophe nesagolide, futhi grey nomnyama iyona mibi kakhulu.

5. Izinyathelo Zokuqaphela Ukuvikela Emuva Kwensimbi Engagqwali

(1) Ngaphambi kwe-argon arc welding, ingemuva le-weldment kufanele livikelwe ngokuligcwalisa nge-argon kusengaphambili.Izinga lokugeleza kufanele libe likhulu.Ngemva kokukhishwa komoya, izinga lokugeleza lizokwehla kancane kancane.Ngesikhathi senqubo ye-welding, ipayipi kufanele igcwaliswe nge-argon ngokuqhubekayo.I-hose ye-argon ingakhishwa kuphela ngemva kokuqedwa kwe-welding ukuze i-weld ivikelwe kahle.

Ngaphezu kwalokho, ukunakwa okukhethekile kufanele kukhokhwe eqinisweni lokuthi i-welding ingenziwa kuphela ngemva kokuba umoya usuphelile, ngaphandle kwalokho umphumela wokuzivikela wokugcwalisa i-argon uzothinteka.

(2) Izinga lokugeleza kwegesi ye-argon kufanele lifanele.Uma izinga lokugeleza lincane kakhulu, ukuvikelwa akukuhle, futhi ingemuva le-weld i-oxidized kalula;uma izinga lokugeleza likhulu kakhulu, amaphutha afana ne-concavity yempande ye-weld azobangelwa, okuthinta ikhwalithi yokushisela.

(3) I-argon gas inlet kufanele ibekwe ngendlela ephansi ngangokunokwenzeka engxenyeni evaliwe, futhi imbobo yokukhipha umoya kufanele ibekwe phezulu kancane engxenyeni yepayipi evaliwe.Ngenxa yokuthi i-argon inzima kunomoya, ukugcwalisa i-argon kusuka endaweni ephansi kungaqinisekisa ukugxila okuphezulu, futhi umphumela wokuvikela wokugcwalisa i-argon uzoba ngcono.

(4) Ukuze kuncishiswe ukulahlekelwa kwegesi ye-argon epayipini elivela ekhaleni eliphakathi kwamalunga, elithinta umphumela wokuvikela futhi likhulise izindleko, i-tape inganamathiselwa eduze kwegebe phakathi kwezihlanganisi zokushisela ngaphambi kokushisela, kusale ubude kuphela. ukushisela okukodwa okuqhubekayo yi-welder, nokususa itheyiphu ngenkathi i-welding.

02

Indlela yokuvikela izintambo zokushisela ozivikelayo

Intambo yokushisela ezivikela yona ngemuva iyintambo yokushisela ene-coating.Ngesikhathi sokushisela, ukunamathela kwayo okuyisivikelo kuzobamba iqhaza ekuvikelweni okuphelele kwangaphambili nangemuva kwechibi elincibilikisiwe, kwakhiwe ungqimba oluqinile lokuvikela ukuvimbela ingemuva le-weld bead ekubeni i-oxidized.Lesi sendlalelo esiyisivikelo sizowa ngokuzenzakalelayo ngemva kokupholisa, futhi sizohlanzwa futhi sihlolwe phakathi nokuhlolwa kwengcindezi.izosulwa.

Indlela yokusebenzisa yalolu hlobo lwentambo yokushisela ngokuyisisekelo iyafana neyejwayelekile i-argon arc welding solid core wire, futhi ukusebenza kwensimbi yokushisela kungahlangabezana nezidingo.

I-self-protect welding wire ayinqunyelwe izimo ezihlukahlukene ze-welding, okwenza ukulungiswa kwe-welding kusheshe futhi kube lula.Kodwa-ke, ngenxa yokwemboza phezu kocingo lokushisela, kuzoba nokungahambi kahle lapho izisebenzi zokushisela zisebenza.

Ngenxa yokungahambelani nezindlela zokushisela azifanele izintambo zokushisela ezimboziwe, ngezinye izikhathi kuyenzeka amaphutha anjengama-concavities.Ngakho-ke, kunezidingo ezithile zamakhono namasu okusebenza kwabasebenzi be-welding.Ucingo oluzivikelayo lusetshenziswa kangcono kuma-primers ngenxa yezindleko zalo eziphezulu.

Ngaphezu kwalokho, kunezinhlobo eziningi zezintambo zokushisela ezizimele emakethe ongakhetha kuzo, futhi ukusebenza kwazo kuhlukile.

Isikhathi sokuthumela: Sep-21-2023