I-electrode yokushisela iyinduku yensimbi encibilika futhi igcwaliswe ekuhlanganyeleni komsebenzi wokushisela ngesikhathi sokushisela igesi noma i-welding kagesi.Izinto ze-electrode ngokuvamile zifana nempahla yomsebenzi.

Lapha sizoqonda ukuthi i-electrode yokushisela yakhiwa kanjani:

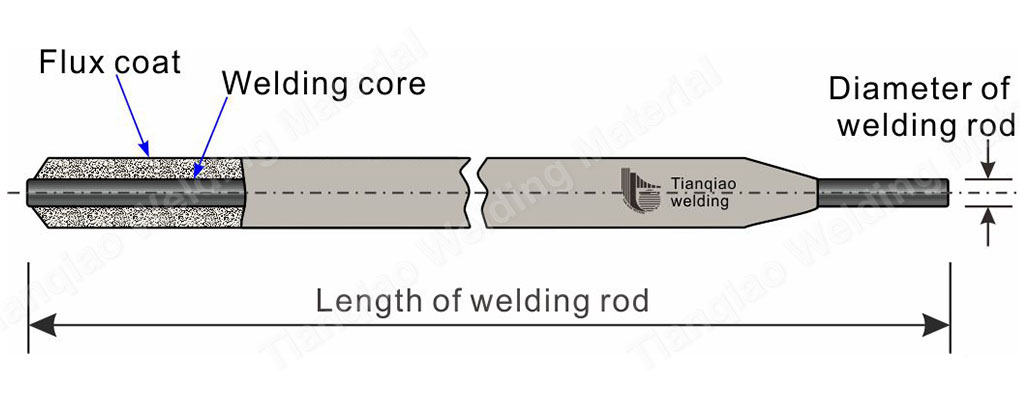

Umfanekiso 1 Isakhiwo se-electrode yokushisela i-Tianqiao

I-electrode yokushisela i-electrode encibilikayo ehlanganiswe ne-coating ye-arc welding yenduku yokushisela.Yakhiwe nge-coating kanye ne-welding core.

Ingqikithi yensimbi embozwe i-coating ku-welding stick ibizwa ngokuthii-welding core.I-welding core ngokuvamile iyintambo yensimbi enobude nobubanzi obuthile.

Umfanekiso we-2 I-Core of Tianqiao welding electrode

Imisebenzi emibili yengqikithi

1. Yenza i-welding current futhi ukhiqize i-arc ukuguqula amandla kagesi abe ukushisa.

2. I-welding core ngokwayo iyancibilika njengensimbi yokugcwalisa futhi ihlanganiswe ne-liquid base metal ukwenza i-weld.Lapho ushisela nge-electrode, insimbi ewumgogodla ithatha ingxenye yayo yonke insimbi yokushisela.Ngakho-ke, ukwakheka kwamakhemikhali we-weld core kuthinta ngqo ikhwalithi ye-weld.Ngakho-ke, intambo yensimbi esetshenziswa njengengqikithi ye-electrode inomkhiqizo wayo kanye nokwakheka okucacisiwe ngokwehlukana.

Ukufakwa kwe-electrodeibhekisela kungqimba lokumboza olusetshenziswa ebusweni bomgogodla wokushisela.I-coating ibolile futhi iyancibilika enqubweni yokushisela ukuze kwakhiwe igesi kanye ne-slag, edlala indima ekuvikelweni kwemishini, ukwelashwa kwe-metallurgical, kanye nokwenza ngcono ukusebenza kwenqubo.

Umfanekiso wesi-3 Ukumbozwa kwe-electrode yokushisela ye-Tianqiao

Ukwakheka kokumboza kuhlanganisa: amaminerali (njengemabula, i-fluorspar, njll.), ama-ferroalloys nezimpushana zensimbi (njenge-ferromanganese, i-ferro-titanium, njll.), izinto eziphilayo (njengofulawa wezinkuni, i-cellulose, njll.), imikhiqizo yamakhemikhali (njenge-titanium dioxide, ingilazi yamanzi, njll.).Ukufakwa kwe-Electrode kuyisici esibalulekile ekunqumeni ikhwalithi yama-welds.

Imisebenzi eyinhloko yokumboza ohlelweni lwe-welding

1. Thuthukisa ukuzinza kokuvutha kwe-arc:

I-electrode engahlanganisiwe akulula ukuthungela i-arc.Ngisho noma ivutha, ayikwazi ukuvutha ngokuqinile.

2. Vikela i-weld pool:

Phakathi nenqubo yokushisela, umoya-mpilo, i-nitrogen kanye nomhwamuko wamanzi emoyeni ungena emthungoni we-weld, okuzoba nomthelela omubi ku-weld seam.Akukhona nje ukwakheka kwama-pores, kodwa futhi kunciphisa izakhiwo zemishini ye-weld, futhi kubangele imifantu.Ngemva kokuba i-electrode coating incibilike, inani elikhulu legesi likhiqizwa elimboza i-arc kanye nedamu elincibilikisiwe, elizonciphisa ukuxhumana phakathi kwensimbi encibilikisiwe nomoya.Lapho i-weld ipholile, i-coating encibilikile yenza ungqimba lwe-slag, oluhlanganisa ubuso be-weld, ivikela insimbi ye-weld futhi ipholise kancane, inciphisa amathuba okuba ne-porosity.

Okwesithathu, ukuqinisekisa ukuthi i-weld i-deoxidized futhi i-desulfurized kanye nokungcola kwe-phosphorus

Nakuba ukuvikelwa kwenziwa ngesikhathi senqubo yokushisela, kusengenakugwemeka ukuthi inani elincane le-oksijini lizongena echibini elincibilikisiwe ukuze lifake izakhi zensimbi ne-alloy, lishise izakhi ze-alloy, futhi linciphise izinga lokushisela.Ngakho-ke, kuyadingeka ukwengeza i-ejenti yokunciphisa (njenge-manganese, i-silicon, i-titanium, i-aluminium, njll.) embotsheni ye-electrode ukunciphisa ama-oxide angene echibini elincibilikisiwe.

4. Faka izakhi ze-alloying zokushisela:

Ngenxa yomphumela wokushisa ophezulu we-arc, izakhi ze-alloying zensimbi ye-weld zizokhishwa futhi zishiswe, okuzonciphisa izakhiwo zemishini ye-weld.Ngakho-ke, kuyadingeka ukwengeza izakhi ezifanele ze-alloying ku-weld ngokusebenzisa i-coating ukukhokhela ukulahlekelwa okushisiwe kwezakhi ze-alloy nokuqinisekisa noma ukuthuthukisa izakhiwo zemishini ye-weld.Ukuze kushiswe ezinye izinsimbi ze-alloy, kuyadingeka futhi ukuthi kufakwe i-alloy ku-weld ngokusebenzisa i-coating, ukuze insimbi ye-weld ibe seduze nokwakheka kwensimbi yensimbi eyisisekelo, futhi izakhiwo zemishini zingabamba noma zidlule. isisekelo sensimbi.

5. Thuthukisa ukukhiqiza kwe-welding futhi unciphise i-spatter:

I-electrode coating inomphumela wokwandisa i-droplet nokunciphisa i-spatter.Iphuzu elincibilikayo le-electrode coating liphansi kancane kunephuzu lokushisela lomgogodla.Kodwa-ke, ngenxa yokuthi i-welding core iphakathi nendawo ye-arc futhi izinga lokushisa liphakeme kakhulu, i-welding core iyancibilika kuqala, futhi okunamathelayo kuyancibilika kamuva.Ngesikhathi esifanayo, njengoba ukulahlekelwa kwensimbi okubangelwa i-spatter kuncishisiwe, i-coefficient yokubeka iyanda, futhi ukukhiqizwa kwe-welding nakho kuyathuthukiswa.

Isikhathi sokuthumela: Jun-01-2021