I-Electrode arc welding iyindlela yokushisela esetshenziswa kakhulu ekukhiqizeni izimboni.Insimbi okufanele ishiselwe isigxobo esisodwa, kanti i-electrode enye isigxobo.Lapho izigxobo ezimbili zisondelene, i-arc ikhiqizwa.Ukushisa okukhiqizwa ukukhishwa kwe-arc (okuvame ukubizwa ngokuthi i-arc combustion) kusetshenziselwa ukuxhuma i-electrode ne-workpieces encibilike futhi yakhe i-weld ngemva kokujiya, ukuze kutholwe inqubo yokushisela ngokuhlanganyela okuqinile.

Umfanekiso 1. Umlando we-welding

Umlando omfushane

Ngemva kokuhlolwa okuningi kokushisela ekuqaleni kwekhulu le-19, iNgisi okuthiwa uWillard laqala ukuthola ilungelo lobunikazi lokushisela i-arc ngo-1865. Wasebenzisa amandla kagesi ukuze adlule izingcezu zensimbi ezimbili ukuze azihlanganise ngempumelelo, futhi cishe eminyakeni engamashumi amabili kamuva, umRashiya. okuthiwa uBernard wathola ilungelo lobunikazi lenqubo yokushisela i-arc.Wagcina i-arc phakathi kwe-carbon pole kanye nezinto zokusebenza.Lapho i-arc isetshenziswa ngesandla ngokuhlanganyela kwezinto zokusebenza, izinto zokusebenza okufanele zishiselwe zazihlanganiswa ndawonye.Ngawo-1890, insimbi eqinile yathuthukiswa njenge-electrode, eyashiswa echibini elincibilikisiwe futhi yaba yingxenye yensimbi yokushisela.Nokho, umoya-mpilo ne-nitrogen emoyeni kwakha ama-oxide nama-nitride ayingozi ensimbi yokushisela., Ngaleyo ndlela kuholela kukhwalithi embi yokushisela.

Ekuqaleni kwekhulu lama-20, ukubaluleka kokuvikela i-arc ukugwema ukungena emoyeni kuye kwabonakala, futhi ukusetshenziswa kokushisa kwe-arc ukubola ukumbozwa ku-electrode yesivikelo segesi sokuzivikela kwaba yindlela engcono kakhulu.Maphakathi nawo-1920, i-electrode ehlanganisiwe yathuthukiswa, eyathuthukisa kakhulu ikhwalithi yensimbi eshiselwe.Ngesikhathi esifanayo, kungase kube ukuguqulwa okubaluleke kakhulu kwe-arc welding.Imishini eyinhloko enqubweni yokushisela ihlanganisa umshini wokushisela kagesi, izindlawu zokushisela kanye nemaski yobuso.

Umfanekiso 2. Isimiso sokushisela

Umfanekiso 2. Isimiso sokushisela

Isimiso

I-arc yokushisela inikwa amandla ngumthombo wamandla wokushisela.Ngaphansi kwesenzo se-voltage ethile, kwenzeka into eqinile futhi ehlala isikhathi eside yokukhishwa phakathi kwe-electrode (kanye nokuphela kocingo lokushisela noma induku yokushisela) kanye nomsebenzi.Ingqikithi ye-arc yokushisela i-gas conduction, okungukuthi, igesi engathathi hlangothi endaweni lapho i-arc itholakala khona ichithwa ibe yi-ion ene-positive charged kanye nama-electron aphethwe kabi ngaphansi kwesenzo se-voltage ethile, ebizwa ngokuthi i-ionization.Lezi zinhlayiya ezimbili ezikhokhisiwe ziqondiswe ezigxotsheni ezimbili.Ukunyakaza kokuqondisa kwenza igesi yendawo iqhube ugesi ukuze yakhe i-arc.I-arc kagesi iguqula amandla kagesi abe ukushisa, okushisisa futhi kuncibilikise insimbi yakhe ilunga elishiselwe.

Ngemuva kokuthi i-arc iholelwe ukuthi "ivutha", inqubo yokukhipha ngokwayo ingakhiqiza izinhlayiya ezikhokhiswayo ezidingekayo ukuze kugcinwe ukukhishwa, okuyinto eqhubekayo yokukhishwa okuzimele.Futhi inqubo yokukhishwa kwe-arc ine-voltage ephansi, yamanje ephezulu, izinga lokushisa eliphezulu kanye ne-luminescence eqinile.Ngale nqubo, amandla kagesi aguqulwa abe amandla okushisa, omshini kanye nokukhanya.I-Welding ikakhulukazi isebenzisa amandla ayo ashisayo kanye nemishini ukuze kuzuzwe inhloso yokuxhuma izinsimbi.

Ngesikhathi sokushisela, i-arc iyasha phakathi kwenduku yokushisela kanye nezinto zokusebenza zokushisela, incibilikisa izinto zokusebenza kanye ne-electrode core ukuze kwakheke ichibi elincibilikisiwe.Ngesikhathi esifanayo, i-electrode coating nayo iyancibilika, futhi ukusabela kwamakhemikhali kwenzeka ukwakha i-slag negesi, okuvikela ukuphela kwe-electrode, amaconsi, ichibi elincibilikisiwe kanye nensimbi ye-weld ephezulu yokushisa.

Ukuhlukaniswa okuyinhloko

Izindlela zokushisela ze-arc ezijwayelekile ikakhulukazi zifaka iShielded Metal Arc Welding (SMAW), i-Submerged Arc Welding (SAW), i-Gas Tungsten Arc Weld (GTAW noma i-TIG welding), i-Plasma Arc Welding (PAW) kanye ne-Gas Metal Arc Welding (GMAW, MIG noma MAG Welding). ) njll.

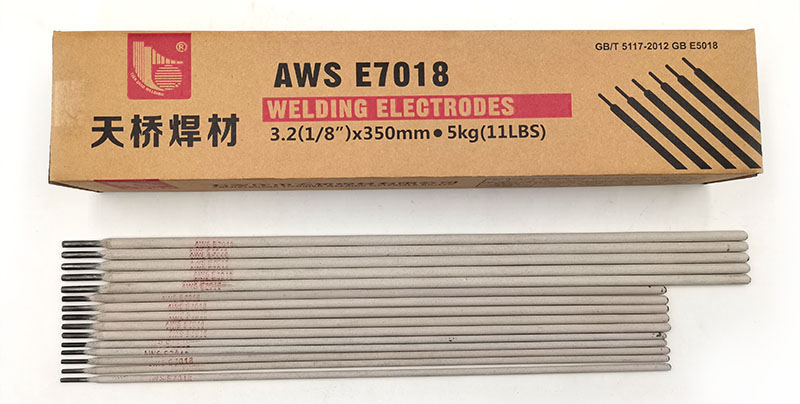

Umfanekiso 3. E7018 welding electrode

Ishielded Metal Arc Welding (SMAW)

Ukushisela i-arc yensimbi evikelekile kusebenzisa i-electrode kanye ne-workpiece njengama-electrode amabili, futhi amandla okushisa namandla aphephetha e-arc asetshenziselwa ukuncibilikisa indawo yokusebenza ngesikhathi sokushisela.Ngesikhathi esifanayo, ngaphansi kwesenzo sokushisa kwe-arc, ukuphela kwe-electrode kuyancibilika ukuze kwakhiwe i-droplet, futhi i-workpiece iyancibilika kancane ukuze yakhe umgodi we-oval ogcwele insimbi ewuketshezi.Insimbi ewuketshezi encibilikisiwe kanye neconsi lendwangu yokusebenza yakha ichibi elincibilikisiwe.Phakathi nenqubo yokushisela, i-coating kanye ne-non-metal yizinto ezihlanganisiwe ezihlakazekayo futhi zakha into engeyona insimbi emboza ubuso be-weld ngokusebenzisa izinguquko zamakhemikhali ezibizwa ngokuthi i-slag.Njengoba i-arc inyakaza, ichibi elincibilikisiwe liyaphola futhi liqine libe ukushisela.Sine-electrode ehlukahlukene yokushisela ye-SMAW, amamodeli aziwa kakhuluE6010, E6011, E6013, E7016, E7018, futhiinsimbi engagqwali, Insimbi, ubuso obuqinilenjll.

Umfanekiso 4. I-arc welding engaphansi kwamanzi

Umfanekiso 4. I-arc welding engaphansi kwamanzi

I-Summerged Arc Welding (SAW)

I-arc welding engaphansi kwamanzi iyindlela lapho i-arc ishisa ngaphansi kwesendlalelo se-flux yokushisela.I-electrode yensimbi esetshenziswa ekushiseleleni i-arc engaphansi kwamanzi iyintambo engenalutho efakwa ngokuzenzakalelayo ngaphandle kokuphazamiseka.Ngokuvamile, i-welding trolley noma amanye amadivaysi emishini kanye nogesi asetshenziselwa ukubona ukunyakaza okuzenzakalelayo kwe-arc ngesikhathi senqubo yokushisela.I-arc ye-arc welding engaphansi kwamanzi iyasha ngaphansi kwe-granular flux.Ukushisa kwe-arc kuyancibilika futhi kuhwamulise izingxenye ezenziwa ngokuqondile yi-arc yomsebenzi, ukuphela kwentambo yokushisela kanye ne-flux, futhi umhwamuko wensimbi kanye ne-flux uyahwamuka ukuze wenze imbobo evaliwe ezungeze i-arc.Shisa kulo mgodi.Umgodi uzungezwe ifilimu ye-slag eyakhiwe nge-slag ekhiqizwa ukuncibilika kwe-flux.Le filimu ye-slag ayigcini nje ngokuhlukanisa kahle umoya ekuxhumaneni ne-arc kanye nechibi elincibilikisiwe, kodwa futhi ivimbela i-arc ekuphumeni.Intambo yokushisela eshisiswe futhi incibilikiswe yi-arc iwe ngendlela yamaconsi bese ihlangana nensimbi encibilikisiwe yokwenza ichibi elincibilikisiwe.I-slag engaminyene kancane intanta echibini elincibilikisiwe.Ngaphezu kokuhlukaniswa nokuvikelwa kwensimbi yechibi elincibilikisiwe, i-slag encibilikisiwe nayo ibhekana nokusabela kwe-metallurgical nensimbi yechibi elincibilikisiwe ngesikhathi senqubo yokushisela, ngaleyo ndlela ithinte ukwakheka kwamakhemikhali ensimbi yokushisela.I-arc iya phambili, futhi insimbi yechibi elincibilikisiwe iphola kancane kancane bese icwebezela ukuze yakhe ukushisela.Ngemva kokuba i-slag encibilikisiwe entanta engxenyeni engenhla yechibi elincibilikisiwe iphola, kwakheka uqweqwe lwe-slag ukuze luqhubeke nokuvikela i-weld ekushiseni okuphezulu futhi ivimbele ukuba i-oxidized.Sihlinzeka nge-flux ye-SAW,I-SJ101,I-SJ301,I-SJ302

Umfanekiso 5. Igesi ye-Tungsten Arc Weld-TIG

Umfanekiso 5. Igesi ye-Tungsten Arc Weld-TIG

Gas Tungsten Arc Weld/Tungsten Inert Gas Welding (GTAW noma TIG)

I-TIG welding ibhekisela endleleni yokushisela i-arc esebenzisa i-tungsten noma i-tungsten alloy (i-thorium tungsten, i-cerium tungsten, njll.) njenge-electrode ne-argon njengegesi evikelayo, ebizwa ngokuthi i-TIG welding noma i-GTAW.Ngesikhathi se-welding, i-filler metal ingangezwa noma ingafakwa ngokuvumelana nefomu le-groove ye-weld kanye nokusebenza kwensimbi ye-weld.I-filler metal ivame ukungezwa kusukela ngaphambili kwe-arc.Ngenxa yolwazi lwe-aluminium-magnesium nezinto zayo ze-alloy, i-AC tungsten arc welding iyadingeka ekushiseleni, kanti i-DC tungsten arc welding isetshenziselwa ezinye izinto zensimbi.Ukuze ulawule okokufaka ukushisa, i-pulsed argon tungsten arc welding isetshenziswa kabanzi.Izintambo zokushisela ezisetshenziswa kakhulu ze-TIG ziyiI-AWS ER70S-6, I-ER80S-G,ER4043,ER5356,HS221kanye nokunye.

Umfanekiso 5. I-Plasma Arc Welding

Umfanekiso 5. I-Plasma Arc Welding

I-Plasma Arc Welding (PAW)

I-Plasma arc iwuhlobo olukhethekile lwe-arc.I-arc iphinde ibe yi-tungsten noma i-tungsten alloy (i-thorium tungsten, i-cerium tungsten, njll.) njenge-arc electrode, isebenzisa i-argon njengegesi evikelayo, kodwa i-electrode ye-tungsten ayiphumeleli ngaphandle kwe-nozzle, kodwa ihoxise Ngaphakathi kwe-nozzle, i-nozzle. ipholile ngamanzi, eyaziwa nangokuthi umlomo wombhobho opholile ngamanzi.Igesi ye-inert ihlukaniswe izingxenye ezimbili, ingxenye eyodwa igesi ekhishwa phakathi kwe-electrode ye-tungsten kanye nozzle opholile ngamanzi, okuthiwa igesi ye-ion;enye ingxenye igesi ekhishwa phakathi kwe-nozzle epholile ngamanzi kanye ne-hood yegesi evikelayo, ebizwa ngokuthi i-Shielding gas, isebenzisa i-plasma arc njengomthombo wokushisa wokushisela, ukusika, ukufafaza, ukuvela phezulu, njll.

Umfanekiso we-5 Welding ye-Metal-Inert Gas

Umfanekiso we-5 Welding ye-Metal-Inert Gas

I-Metal Inert Gas Welding (MIG)

Ukushisela i-MIG kusho ukuthi intambo yokushisela ithatha indawo ye-electrode ye-tungsten.I-wire welding ngokwayo ingenye yezigxobo ze-arc, idlala indima yokuqhutshwa kukagesi kanye ne-arcing, futhi ngesikhathi esifanayo njengento yokugcwalisa, eqhubeka incibilika futhi igcwaliswe ku-weld ngaphansi kwesenzo se-arc.Igesi yokuvikela evame ukusetshenziswa ezungeze i-arc ingaba igesi ye-inert Ar, igesi esebenzayo CO2, noma i-Ar+CO2igesi exubile.I-MIG yokushisela esebenzisa i-Ar njengegesi evikelayo ibizwa ngokuthi i-MIG welding;I-MIG welding esebenzisa i-CO2njengoba igesi yokuvikela ibizwa nge-CO2ukushisela.Inani eliphakeme kakhulu lama-MIGI-AWS ER70S-6, I-ER80S-G.

Isikhathi sokuthumela: Aug-17-2021