IZICELO:

Isetshenziselwa ukushisela uhlobo olufanayo lwensimbi engagqwali engashi esebenza ngaphansi kwezimo zokushisa eziphezulu, kanye nokushisela izinsimbi ze-chrome eziqinile (ezifana ne-Cr5Mo, Cr9Mo, Cr13, Cr28 nokunye.) nezinsimbi ezingafani.

IZIMPAWU:

E310-16iyi-electrode yensimbi engenasici ye-Cr26Ni21 yemishini ye-rutile yengcindezi yesikhumba.Kokubili i-AC ne-DC ingasetshenziswa kukho konke ukushisela isikhundla.Le electrode inokusebenza okuhle kwenqubo yokushisela, futhi insimbi efakiwe inokumelana okuhle kakhulu kwe-oxidation ngaphansi kwezimo zokushisa eziphakeme ezingama-900-1100 ℃.

QAPHELA:

1. Ngaphambi kokushisela, i-electrode izobhakwa ku-300-350℃ ihora elingu-1 futhi isetshenziswe njengoba kudingeka.

2. Susa ukugqwala, amafutha, umswakama nokunye ukungcola ngaphambi kokushisela.

3. Kunconywa ukunikezwa kwamandla kagesi we-DC, ngoba ukujula kwe-welding yamanje akujulile, okwamanje akufanele kube kukhulu kakhulu, ukuze kugwenywe ukubomvu nokuqhekeka kwesikhumba.

4. Yehlisa okokufaka ukushisa ngangokunokwenzeka, futhi i-swing amplitude ye-electrode akufanele ibe nkulu kakhulu.

5. Shisisa futhi ugcine izinga lokushisa phakathi kwamashaneli lingaphansi kuka-150℃.

IZIKHUNDLA ZOKUSHISA:

PA, PB, PC, PD, PE, PF

UKWAKHIWA KWAKHEMICAL YAYO YONKE IMETALI YOKUSHISA: (Wt. %)

| Izinto | C | Mn | Si | S | P | Ni | Cr | Mo | Cu |

| Izimfuneko | 0.08-0.20 | 25.0-28.0 | ≤0.75 | ≤0.03 | ≤0.03 | 20.0-22.5 | 25.0-28.0 | ≤0.75 | ≤0.75 |

| Imiphumela Ejwayelekile | 0.11 | 0.89 | 0.69 | 0.010 | 0.025 | 20.86 | 26.21 | 0.05 | 0.08 |

IZIMPAHLA ZOMKHETHI ZAYO YONKE I-WELD METAL:

| Izinto | Rm/MPa | A/% |

| Izimfuneko | ≥550 | ≥25 |

| Imiphumela Ejwayelekile | 605 | 38 |

IZINQUBO ZOKUSEBENZA EZIJWAYELEKILE: (AC noma DC+)

| Ububanzi (mm) | 2.0 | 2.5 | 3.2 | 4.0 | 5.0 |

| Okwamanje (A) | 25-50 | 50-80 | 80-110 | 110-160 | 160-200 |

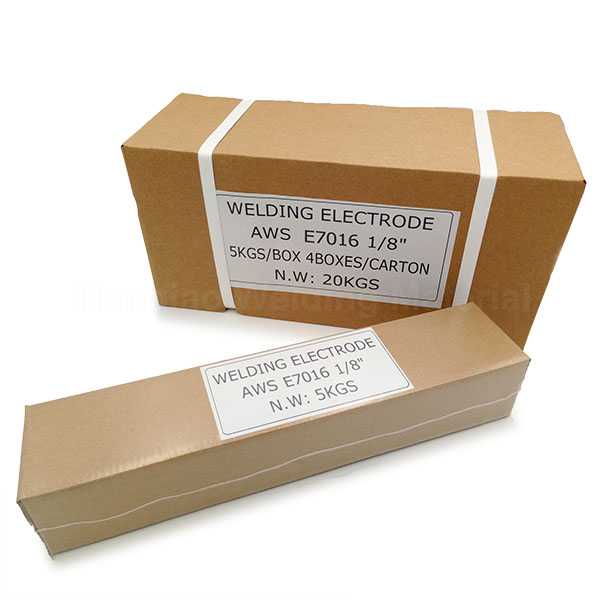

UKUPAKASHA:

5kg/ibhokisi, 4boxes/ibhokisi, 20kgs/ibhokisi, 50cartons/pallet.21MT -26MT nge-1X20″ FCL.

Ukuhlolwa kokuqina kwama-welds:

Kumashisela anomfutho wokusebenza kwawo ongaphansi kuka-0.3MPa, uphalafini ungasetshenziselwa ukuhlolwa kokuvala.Ukuhlolwa kuzokwenziwa ngokuhambisana nalokhu okulandelayo: 5.1.1.1 Izinga lokushisa ngesikhathi sokuhlolwa akufanele libe ngaphansi kuka-5°C.

Gcoba ingaphandle lesiqephu sokuhlola ngempushana emhlophe, bese ugcoba uphalafini owanele ngaphakathi.Ngokuvamile, ngemva kwemizuzu engu-15 kuya kwengama-30, uma kungekho amabala amafutha amnyama endaweni eyimpuphu emhlophe, i-weld ibhekwa njengento engenasici.Ngokuphambene nalokho, kuyadingeka ukususa indawo enesici futhi uphinde u-soldering, bese wenza ukuhlolwa.

Lapho usebenzisa ingcindezi ye-hydraulic ukuze uhlole ukuqina kwesiqukathi, kufanele wenziwe ngokuhambisana nemithethonqubo elandelayo:

Ingcindezi yokuhlola kufanele ikhuphuke kancane ingabi ngaphansi kuka-1.5 izikhathi zokucindezela kokusebenza.

Lapho i-weldment ifinyelela ukucindezela kokuhlolwa, ingcindezi kufanele igcinwe imizuzu emi-5.Uma ukuvuza noma umswakama kutholakala endaweni yokushisela, ingxenye enesici kufanele imakwe, isuswe, ifakwe kabusha, bese ihlolwa.

Ngesikhathi sokuhlolwa kwengcindezi ye-workpiece, akuvunyelwe ukulungisa i-weld;futhi lapho i-workpiece ingaphansi kwengcindezi yokuhlolwa, ayivunyelwe ukushaya i-weld.

Ukuhlolwa kokusebenza kwemishini kwama-welds:

Isampula yokuhlola izothathwa kumasampula anento efanayo kanye nemingcele yenqubo yezingxenye ezishiselwe.

Uhlobo nosayizi wokuhlolwa kokusebenza kufanele kuhambisane nezindinganiso ezifanele ze-GB/T 2649~2653.

i-electrode, i-electrode, i-welding,i-electrode ye-weldingama-electrode welding,induku yokushisela,izinduku zokushisela,intengo ye-electrode yokushisela,intengo yefektri yokushisela,intengo yokushisela,induku yokushisela,izinduku zokushisela,izinduku zokushisela,induku ye-electrode,izinto ezisetshenziswayo zokushisela,izinto ezisetshenziswayo zokushisela,I-electrode yaseChina,i-electrode yokushisela yaseChina,i-carbon steel welding electrode, carbon steel welding electrode,welding electrode factory,I-electrode yokushisela yaseChina,I-electrode yokushisela yaseChina,intengo yenduku yokushisela,impahla yokushisela,impahla yokushisela,impahla yokushisela emhlabeni wonke,i-arc welding,impahla yokushisela,i-arc welding,insimbi yokushisela,i-easy arc welding electrode,i-arc welding i-electrode, i-arc welding electrode, i-electrode ye-welding eqondile, intengo yama-electrode wokushisela, i-electrode yokushisela eshibhile, ama-electrodes welding acid, i-alkaline welding electrode, i-cellulosic welding electrode, ama-electrode welding ase-china, i-electrode yasefekthri, ama-electrodes welding amancane, izinto zokushisela, izinto zokushisela, ukushisela intonga, intonga yokushisela i-electrode, induku yokushisela i-nickel, j38.12 e6013, izinduku zokushisela e7018-1, induku yokushisela, induku yokushisela 6010, i-welding electrode e6010, induku yokushisela e7018, i-welding electrode e6011, i-welding stick 7, i-electrodes engu-7 ama-electrodes e-7018, ama-welding rod 6013, ama-welding rods 6013, i-welding electrode 6013, i-welding electrode e6013,6010 induku ye-welding, i-electrode yokushisela engu-6010, i-6011 ye-welding, ama-electrodes angu-6011, i-welding 6013 i-welding3, i-electrod 60 ama-electrode,7024 welding rod,7016 welding rod,7018 welding rod,7018 welding rods,7018 welding electrode,7018 welding electrode,welding electrode e7016,e6010 welding rod,e6011 welding rod,e6013 welding,18 welding,18 e6013 welding electrode,e7018 welding electrode,e7018 welding electrode,J421 welding electrode,J422 welding electrode,welding electrode J422,wholesale e6010,wholesale e6011,wholesale e6013,wholesale e7013 welding, electrode welding2, electrode welding2, electrode welding de, insimbi yokushisela induku, i-electrode yensimbi engagqwali, i-SS welding electrode, i-welding rods e307, i-welding electrode e312,309l induku yokushisela, i-316 welding electrode, i-e316l 16 i-electrode yokushisela, i-cast iron welding electrode, i-aws Eni-Ci, i-aws Enife-Ci, i-surfacing ukushisela,induku yokushisela ebheke kanzima,i-hard surfacing welding,hardfacing welding,welding,welding,vautid welding,bohler welding,lco welding,miller welding,atlantic welding,welding,flux powder,welding flux,welding powder,welding electrode flux material,welding electrode flux,welding electrode material,tungsten electrode,tungsten electrode,welding wire,argon arc welding,mig welding,tig welding,gas arc welding,gas metal arc welding,ugesi yiwelding,i-arc welding kagesi,i-arc welding rods,i-carbon arc welding ,i-e6013 induku yokushisela isebenzisa,izinhlobo zama-electrode wokushisela,i-flux core welding,izinhlobo zama-electrode ekushiseleni,impahla yokushisela,insimbi yokushisela,insimbi yokushisela,insimbi evikelekile i-arc welding,i-aluminium welding,i-aluminium yokushisela nge-mig,i-aluminium mig welding,ipayipi yokushisela, izinhlobo zokushisela,izinhlobo zenduku yokushisela,zonke izinhlobo zokushisela,izinhlobo zenduku yokushisela,i-6013 welding rod amperage,welding rods electrode,welding electrode specication,welding electrode classification,welding electrode aluminium,welding electrode diameter,welding steel mild,stainless steel welding, I-e6011 welding rod isebenzisa, osayizi bezinduku zokushisela, intengo yezinduku zokushisela, usayizi we-welding electrode, ama-aws e6013, ama-aws e7018, ama-aws er70s-6, intambo yokushisela yensimbi engenasici, i-stainless steel mig welding wire, i-tig welding wire, induku yokushisela ephansi, 6011 rod amperage,4043 welding rod,cast iron welding rod,western welding academy,sanrico welding rods,aluminium welding,aluminium welding rod,imikhiqizo yokushisela,i-welding tech,imboni yokushisela

Okwedlule: I-Stainless Steel Welding Electrode AWS E309L-16(A062) Olandelayo: Insimbi engagqwali Welding Electrode AWS E312-16