IZICELO:

Isetshenziselwa ukushisela i-high carbon steel, insimbi yamathuluzi nezinsimbi ezingafani

IZIMPAWU:

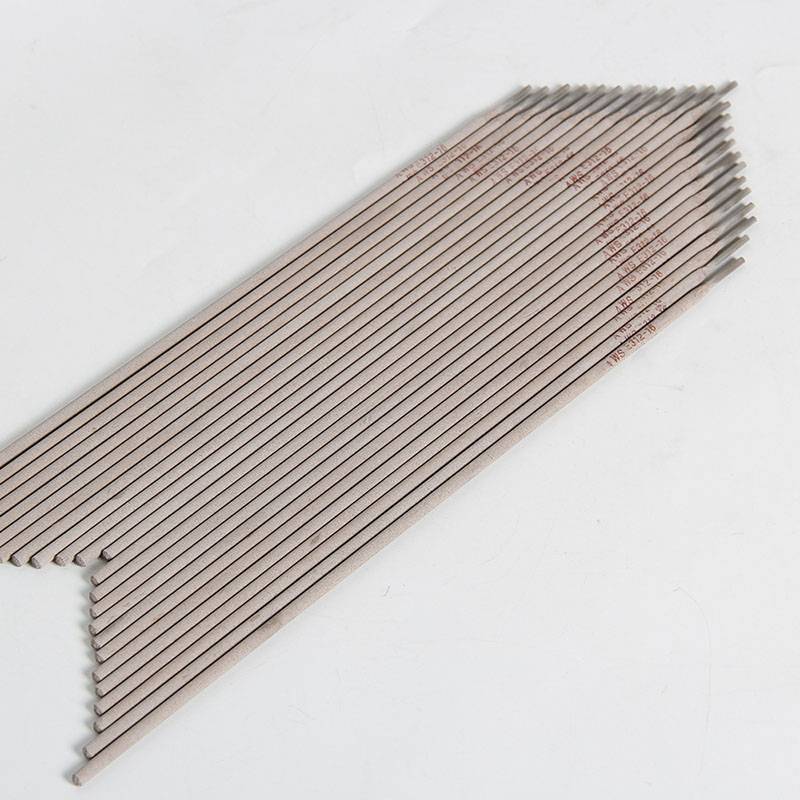

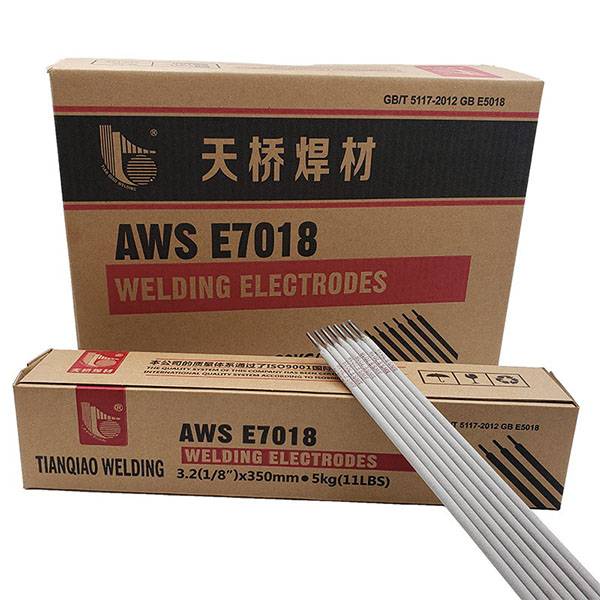

I-E312-16 iyi-electrode yensimbi engagqwali eyiduplex ene-titanium-calcium coating.Ukusebenza kwenqubo yokushisela kuhle kakhulu, futhi kungasetshenziselwa kokubili i-AC ne-DC.Ngenxa yokuthi i-weld iqukethe cishe u-40% we-ferrite, inokumelana nokuqhekeka okuhle kakhulu

QAPHELA:

1. Ngaphambi kokushisela, i-electrode izobhakwa ku-300-350℃ ihora elingu-1 futhi isetshenziswe njengoba kudingeka.

2. Susa ukugqwala, amafutha, umswakama nokunye ukungcola ngaphambi kokushisela.

3. Ukuze uthole insimbi eqinile, lapho usebenzisa i-current encane ukushisela ama-workpieces ayinkimbinkimbi futhi awugqinsi, ama-workpieces kufanele ashiswe kuqala ku-150 ℃.

IZIKHUNDLA ZOKUSHISA:

PA, PB, PC, PD, PE, PF

Ukwakheka Kwekhemikhali Kwayo Yonke Insimbi Yokushisela: (Wt. %)

| Izinto | C | Mn | Si | S | P | Ni | Cr | Mo | Cu |

| Izimfuneko | 0.15 | 0.5-2.5 | ≤1.0 | ≤0.03 | ≤0.04 | 8.0-10.5 | 28.0-32.0 | ≤0.75 | ≤0.75 |

| Imiphumela Ejwayelekile | 0.09 | 1.08 | 0.76 | 0.010 | 0.028 | 9.97 | 29.0 | 0.12 | 0.17 |

IZIMPAHLA ZOMKHETHI ZAYO YONKE I-WELD METAL:

| Izinto | Rm/MPa | A/% |

| Izimfuneko | ≥660 | ≥15 |

| Imiphumela Ejwayelekile | 760 | 28 |

IZINQUBO ZOKUSEBENZA EZIJWAYELEKILE: (AC noma DC+)

| Ububanzi (mm) | 2.5 | 3.2 | 4.0 | 5.0 |

| Okwamanje (A) | 50-80 | 80-110 | 130-160 | 160-200 |

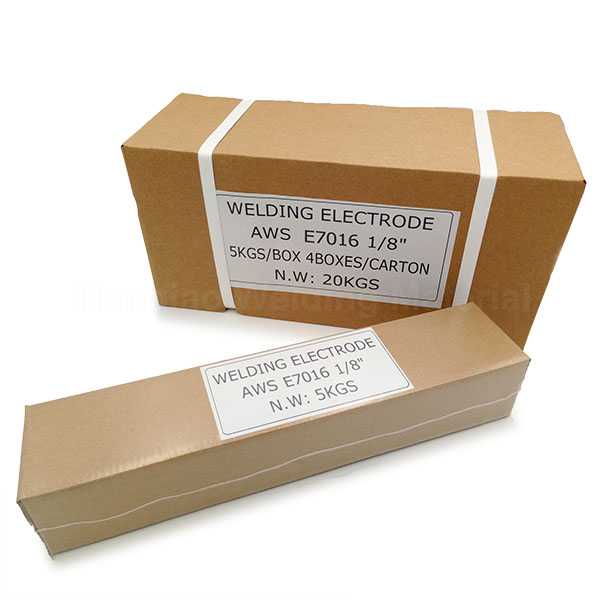

UKUPAKASHA:

5kg/ibhokisi, 4boxes/ibhokisi, 20kgs/ibhokisi, 50cartons/pallet.21MT -26MT nge-1X20″ FCL.

Izidingo zempahla yezingxenye zokushisela:

Izinombolo zensimbi, ukucaciswa kanye nezidingo zokuhleleka kwezinto zokusetshenziswa zezingxenye zokushisela zizohambisana nezidingo zemidwebo noma imibhalo yezobuchwepheshe, futhi uhlelo lokufaka esikhundleni sezinto ezibonakalayo luzosetshenziswa ngokuqinile ukuze kufakwe izinto.

Izinto zezingxenye zokushisela (ipuleti lensimbi, insimbi, induku yokushisela, intambo yokushisela, i-flux kanye negesi yokuvikela, njll.) kufanele ihlolwe futhi yamukelwe ngokuvumelana nezindinganiso zezinto ezibonakalayo lapho kungena efektri.Izinto ezingeke ziqinisekiswe noma ezingenaso isitifiketi sokuhambisana kufanele ziphinde zihlolwe.Ingasetshenziswa.

Lapho ukhetha izinduku zokushisela, izintambo, ama-fluxes namagesi okuvikela izingxenye zokushisela, kufanele kusekelwe esimisweni samandla alinganayo phakathi kwensimbi ye-weld kanye nesisekelo sensimbi ukuze kuqinisekiswe ukuthi insimbi yokushisela ayikho ngaphansi kwezakhiwo zemishini yensimbi eyisisekelo. , futhi kufanele ihambisane ne-GB/ T 5117 ejwayelekile, GB/T 5118 kanye ne-GB/T 8110.

Izinduku zokushisela kanye nama-fluxes anemiyalo ekhethekile kufanele zomiswe ngokuhambisana nezidingo zebhukwana lemiyalo.Ukushisa okomisa ngaphandle kwezidingo ezikhethekile kufanele kuhlangabezane nezidingo zetafula.Yigcine ku-incubator ngemva kokoma, futhi uyikhiphe lapho uyidinga.Induku yokushisela akufanele ibhakwe ngaphezu kokuphindwe kabili.Intambo yokushisela kufanele ihlanzwe ngamafutha namanzi ngaphambi kokusetshenziswa.

electrode,electrode,welding,welding electrode,welding stick,welding rods,welding electrode price,electrode welding,welding rod factory price,welding stick,stick welding,welding stick,china welding rods,stick electrode,welding consumables,welding ezisebenzisekayo,China electrode,welding electrode China,carbon steel welding electrode,carbon steel welding electrode,welding electrode factory,I-electrode yokushisela yaseChina,I-electrode yokushisela yaseChina,intengo yenduku yokushisela,impahla yokushisela,impahla yokushisela,impahla yokushisela emhlabeni wonke,i-arc welding,impahla yokushisela,i-arc welding,insimbi yokushisela,i-easy arc welding electrode,i-arc welding i-electrode,i-arc welding electrode,i-electrode ye-welding eqondile,intengo yama-electrode wokushisela,i-electrode yokushisela eshibhile,ama-electrodes welding acid,i-alkaline welding electrode,i-cellulosic welding electrode,ama-electrode welding yase-china,i-electrode yasefekthri,ama-electrodes welding amancane,impahla yokushisela,impahla yokushisela,i-welding intonga, intonga yokushisela i-electrode, induku yokushisela i-nickel, j38.12 e6013, izinduku zokushisela e7018-1, induku yokushisela, induku yokushisela 6010, i-welding electrode e6010, induku yokushisela e7018, i-welding electrode e6011, i-welding stick 7, i-electrodes engu-7 ama-electrodes e-7018, ama-welding rod 6013, ama-welding rods 6013, i-welding electrode 6013, i-welding electrode e6013,6010 induku ye-welding, i-electrode yokushisela engu-6010, i-6011 ye-welding, ama-electrodes angu-6011, i-welding 6013 i-welding3, i-electrod 60 ama-electrode,7024 welding rod,7016 welding rod,7018 welding rod,7018 welding rods,7018 welding electrode,7018 welding electrode,welding electrode e7016,e6010 welding rod,e6011 welding rod,e6013 welding,18 welding,18 e6013 welding electrode,e7018 welding electrode,e7018 welding electrode,J421 welding electrode,J422 welding electrode J422,wholesale e6010,wholesale e6013,wholesale e7013 welding, electrode welding2, electrode welding2 , insimbi yokushisela induku, i-electrode yensimbi engagqwali, i-SS welding electrode, i-welding rods e307, i-welding electrode e312,309l induku yokushisela, i-316 welding electrode, i-e316l 16 i-electrode yokushisela, i-cast iron welding electrode, i-aws Eni-Ci, i-aws Enife-Ci, i-surfacing ukushisela,induku yokushisela ebheke kanzima,i-hard surfacing welding,hardfacing welding,welding,welding,vautid welding,bohler welding,lco welding,miller welding,atlantic welding,welding,flux powder,welding flux,welding powder,welding electrode flux material,welding electrode flux,welding electrode material,tungsten electrode,tungsten electrode,welding wire,argon arc welding,mig welding,tig welding,gas arc welding,gas metal arc welding,ugesi yiwelding,i-arc welding kagesi,i-arc welding rods,i-carbon arc welding ,i-e6013 induku yokushisela isebenzisa,izinhlobo zama-electrode wokushisela,i-flux core welding,izinhlobo zama-electrode ekushiseleni,impahla yokushisela,insimbi yokushisela,insimbi yokushisela,insimbi evikelekile i-arc welding,i-aluminium welding,i-aluminium yokushisela nge-mig,i-aluminium mig welding,ipayipi yokushisela, izinhlobo zokushisela,izinhlobo zenduku yokushisela,zonke izinhlobo zokushisela,izinhlobo zenduku yokushisela,i-6013 welding rod amperage,welding rods electrode,welding electrode specication,welding electrode classification,welding electrode aluminium,welding electrode diameter,welding steel mild,stainless steel welding, I-e6011 induku yokushisela isebenzisa, osayizi bezinduku zokushisela, intengo yezinduku zokushisela, usayizi wama-electrodes wokushisela, ama-aws e6013, ama-aws e7018, ama-aws er70s-6, intambo yokushisela yensimbi engenasici, i-stainless steel mig welding wire, i-tig welding wire, induku yokushisela ephansi, 6011 rod amperage,4043 welding rod,cast iron welding rod,western welding academy,sanrico welding rods,aluminium welding,aluminium welding rod,imikhiqizo yokushisela,i-welding tech,imboni yokushisela

Okwedlule: I-Stainless Steel Welding Electrode AWS E310-16 (A402) Olandelayo: I-Stainless Steel Welding Electrode AWS E316-16 (A202)