I-Argon tungsten arc welding isebenzisa i-argon njengegesi evikela ukushisa nokuncibilikisa impahla yokushisela ngokwayo (iphinde incibilike lapho insimbi yokugcwalisa ingezwa) ngokusebenzisa i-arc ekhiqizwa phakathi kwe-electrode ye-tungsten nomzimba we-weld, bese yenza ukushisela. we weld metal Way.Ii-tungsten electrode,i-weld pool, i-arc kanye nendawo yomthungo ehlangene eshisiswe yi-arc ivikelekile ekungcoleni komoya ngokugeleza kwe-argon.

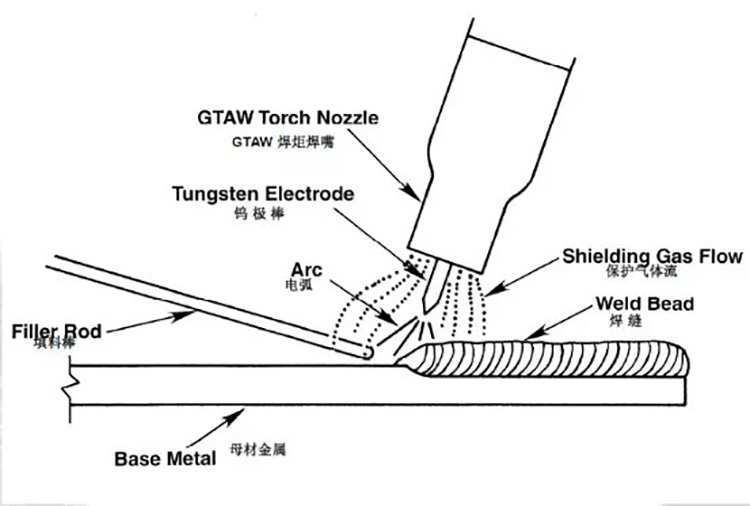

Ngesikhathi sokushisela i-argon arc, izikhundla ezihambisanayo zethoshi, i-filler metal kanye nokushisela kunjengoba kukhonjisiwe esithombeni esingezansi: ubude be-arc ngokuvamile buwu-1 ~ 1.5 ububanzi be-electrode ye-tungsten.Lapho ukushisela kumisiwe, insimbi yokugcwalisa iqala ukukhishwa echibini elincibilikisiwe (i-filler metal yengezwa ngokuvumelana nobukhulu be-weldment), futhi ukuphela okushisayo kusadinga ukuhlala ngaphansi kokuvikelwa kokugeleza kwe-argon ukuvimbela i-oxidation yayo. .

1. Ithoshi yokushisela (ithoshi)

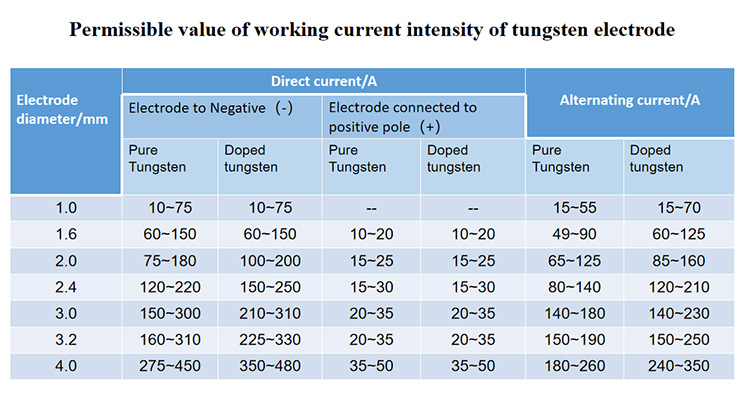

Ngaphezu kokubopha i-electrode ye-tungsten nokuletha i-welding current, ithoshi yokushisela ye-argon tungsten arc (eyaziwa nangokuthi ithoshi lokushisela) nayo idinga ukufafaza igesi evikelayo.Izibhamu zokushisela ezisezingeni eliphezulu zidinga ukusebenzisa izibhamu zokushisela ezipholiswe ngamanzi ukuze zishise isikhathi eside.Ngakho-ke, ukusetshenziswa okufanele nokuvikelwa kwethoshi lokushisela kubaluleke kakhulu.Umthamo wamanje we-Tungsten electrode (A) uboniswa etafuleni elingezansi.

2. Indlela yegesi

Umzila wegesi wakhiwe nge-argon cylinder pressure reduction valve, imitha yokugeleza, ipayipi ne-electromagnetic gas valve (ngaphakathi komshini wokushisela).I-valve yokunciphisa ingcindezi isetshenziselwa ukunciphisa ingcindezi futhi ilungise ukucindezela kwegesi elivikelayo.I-flowmeter isetshenziselwa ukulinganisa nokulungisa ukugeleza kwegesi evikelayo.Imishini yokushisela i-Argon arc ngokuvamile isebenzisa i-flowmeter yokucindezela ehlanganisiwe, elula futhi enokwethenjelwa ukuyisebenzisa.

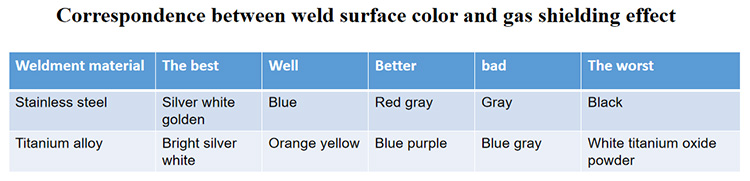

Ngesikhathi sokushisela i-argon arc, imfuneko yokuhlanzeka kwegesi ye-argon ukuthi insimbi engagqwali ye-chromium-nickel kufanele ibe ≥99.7%, futhi insimbi ephikisayo kufanele ibe ≥99.98%.

(1) I-Argon iyigesi engasebenzi, futhi akulula ukusabela nezinye izinto zensimbi namagesi.Ngaphezu kwalokho, ngenxa yomphumela wokupholisa wokugeleza komoya, indawo ye-weld ethintekile ukushisa incane futhi ukuguqulwa kwe-weldment kuncane.Yigesi evikelayo ekahle kakhulu yokushisela i-argon tungsten arc.

(2) I-Argon isetshenziselwa ukuvikela ngempumelelo ichibi elincibilikisiwe, ukuvimbela umoya ekugugulekeni kwechibi elincibilikisiwe futhi kubangele i-oxidation ngesikhathi senqubo yokushisela, futhi ngesikhathi esifanayo ihlukanise ngokuphumelelayo umoya endaweni yokushisela, ukuze indawo yokushisela ivikelwe kanye nokusebenza kwe-welding kuyathuthukiswa.

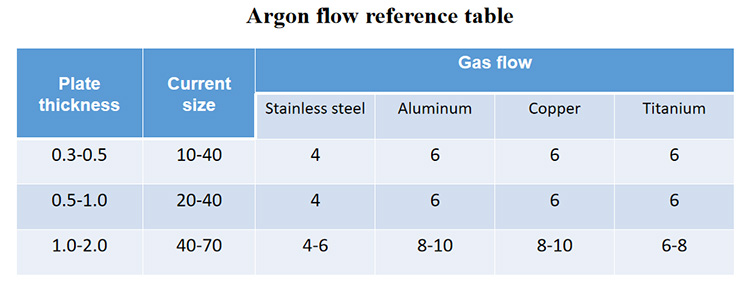

(3) Indlela yokulungisa inqunywa ngokwezinto zensimbi okufanele zishiselwe, usayizi wamanje, kanye nendlela yokushisela: uma imanje inkulu, igesi evikelayo inkulu.Ngezinto ezibonakalayo ezisebenzayo, igesi evikelayo kufanele iqiniswe ukuze kwandiswe izinga lokugeleza.

3. Imingcele yokucaciswa

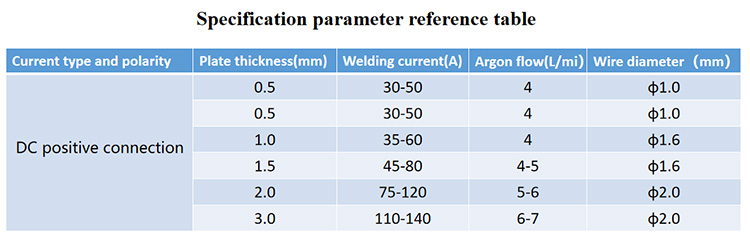

Imingcele ejwayelekile ye-argon tungsten arc welding ikakhulukazi ihlanganisa yamanje, i-voltage, isivinini sokushisela, nokugeleza kwegesi ye-argon, futhi amanani ayo ahlobene nohlobo lwempahla okufanele ishiselwe, ukujiya kwepuleti kanye nohlobo oluhlangene.

Imingcele esele njengobude be-electrode ye-tungsten ephuma emlonyeni ngokuvamile iphinda izikhathi ezingu-1-2 ububanzi be-electrode ye-tungsten, ibanga eliphakathi kwe-electrode ye-tungsten kanye nokushisela (ubude be-arc) ngokuvamile buwu-1.5 ububanzi be-tungsten. i-electrode, nosayizi we-nozzle kunqunywa ngemuva kokunqunywa kwenani lamanje lokushisela.Khetha futhi.

Imininingwane ejwayelekile yensimbi engagqwali ye-argon arc welding imi kanje:

4. Ukuhlanza ngaphambi kokushisela

I-Tungsten argon welding izwela kakhulu ekungcolisweni kwe-weldment kanye ne-filler metal surface, ngakho-ke amafutha, ukugcoba, i-lubricant nefilimu ye-oxide ebusweni be-weldment kufanele isuswe ngaphambi kokushisela.

5. Ubuchwepheshe bokuphepha

Abaqhubi be-argon tungsten arc welding kumele bagqoke imaski yekhanda, amagilavu, izingubo zokusebenza, nezicathulo zokusebenza ukuze bagweme ukusha kwe-ultraviolet kanye ne-infrared ku-arc.Imishini yokushisela ye-Steyr tungsten argon arc ifakwe iziqalisi ze-arc ezinemvamisa ephezulu.Nakuba ugesi we-high-frequency high-frequency high-voltage ngeke ushaqise opharetha, lapho ukusebenza kwe-insulation kungalungile, ugesi we-high-frequency uzoshisa isikhumba sesandla somqhubi , futhi kunzima ukuphulukisa, ngakho-ke ukusebenza kwe-insulation Isibambo se-welding kumele sihlolwe njalo.Ngesikhathi sokushisela kwe-argon tungsten arc, ukungena komoya endaweni yokushisela kufanele kuthuthukiswe.

Qaphela: Into esemqoka ukuba nekhono futhi dexterous.Ubukhulu bebhodi, isikhathi sokuchofoza, kanye nesimanje konke kuhlobene, futhi kudinga ukubambisana komunye nomunye.

Uma ushisela, ungakhombi inaliti endaweni yokushisela ekuqaleni, futhi uyishaye ingenalutho kuqala ukuze ukhiphe umoya epayipini, ukuze i-welding ingaqhume futhi kungabikho amabala amnyama.Imizuzwana embalwa, ngale ndlela, insimbi engagqwali ivikelwe i-argon gas ngesikhathi sokupholisa, ngakho ngeke ibe mnyama, ngisho namanzi okugeza kanye neshidi lokupholisha ligcinwa.Lokhu kungasetshenziswa kuphela ukushisela indawo.Uma uhudula i-welding ibanga elide, ayikho indlela.Ibhodi nakanjani lizoshintsha umbala.Kufanele ulinde ukupholishwa nokuhlanza.

Isikhathi sokuthumela: May-16-2023