I-coating idlala ukusabela okuyinkimbinkimbi kwe-metallurgical kanye nezinguquko zomzimba nezamakhemikhali ohlelweni lokushisela, okuyinto ngokuyisisekelo inqoba izinkinga ekushiseni kwe-electrode yesithombe, ngakho-ke ukugqoka kungenye yezinto eziyinhloko zokunquma ikhwalithi yensimbi yokushisela.

I-Electrode coating:Isho ungqimba olunamathelayo lwento ecolekile ye-granular enezakhiwo ezihlukile zomzimba namakhemikhali eziboshwe ngokulinganayo ebusweni bomongo wokushisela.

Indima yei-electrode ye-weldingukunamathela:Enqubweni yokushisela, yakha i-slag enephuzu elincibilikayo elifanele, i-viscosity, ukuminyana, i-alkalinity nezinye izinto ezibonakalayo namakhemikhali, ukuqinisekisa ukushiswa kwe-arc okuzinzile, ukwenza i-droplet metal inguquko elula, idale umoya ozungeze indawo ye-arc kanye nedamu elincibilikisiwe ukuze kuvikelwe. indawo yokushisela, futhi uthole ukwakheka okuhle kwe-weld nokusebenza.Ngokungeza i-deoxidizer, i-alloying element noma okuqukethwe okuthile kwe-iron powder enamathela, ingahlangabezana nezidingo zokusebenza kwensimbi ye-weld noma ithuthukise ukusebenza kahle kokuncibilika.

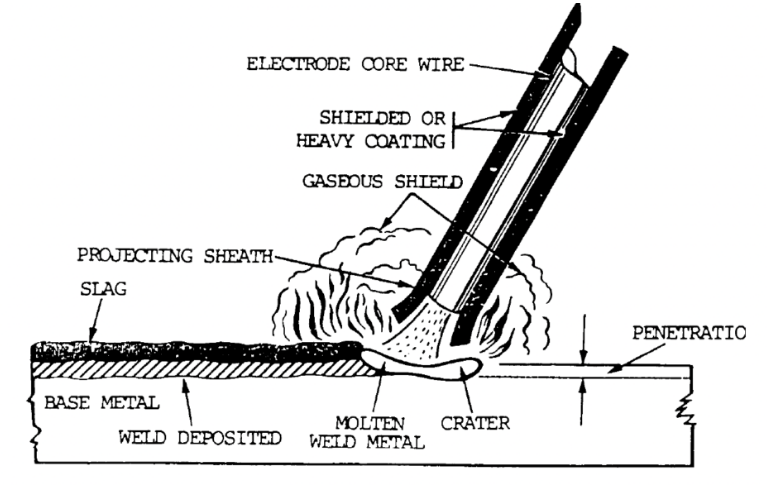

Isimiso se-electrode arc welding:

1. Isikhumba somuthi

2. I-Weld core

3. Vikela igesi

4 :iqo

5. Ichibi elincibilikisiwe

6. Izinto eziyisisekelo

7. Weld

8. Welding slag

9. I-Slag

10. Ncibilikisa amathonsi

Izinto ezisetshenziswayo ezahlukahlukene ngokuya ngendima yazo ekuhlanganiseni kwe-electrode zingahlukaniswa zibe:

(1) I-arc stabilizer

Umsebenzi oyinhloko ukwenza i-electrode ibe lula ukuqala i-arc futhi igcine ukushisa okuzinzile kwe-arc kunqubo yokushisela.Njengezinto zokusetshenziswa kwe-arc stabilizer ngokuyinhloko ezinye eziqukethe inani elithile lezinto eziphansi ze-ionization ezingaba khona kalula, njenge-feldspar, i-sodium silicate, i-rutile, i-titanium dioxide, imabula, i-mica, i-ilmenite, i-ilmenite encishisiwe njalonjalo.

(2) I-ejenti eyenza igesi

Ngaphansi kwesenzo sokushisa okuphezulu kwe-arc igesi yokubola, ukwakha umoya ovikelayo, ukuvikela i-arc nensimbi encibilikisiwe, ukuvimbela ukungena kwe-oksijeni ne-nitrogen emoyeni ozungezile.Ama-agent okwenza igesi asetshenziswa kakhulu yi-carbonate (njengemabula, i-dolomite, i-rhombic acid, i-barium carbonate, njll.) nezinto eziphilayo (njengempushana yokhuni, isitashi, i-cellulose, i-resin, njll.).

(3) I-Deoxidizer (eyaziwa nangokuthi i-ejenti yokunciphisa)

Okuqukethwe komoyampilo ku-weld metal kungancishiswa futhi ukusebenza kwensimbi yokushisela kungathuthukiswa ngokusabela kwe-chemical metallurgical kunqubo yokushisela.I-Deoxidizer ikakhulukazi iqukethe izakhi ze-iron alloy kanye nempushana yensimbi ehambisana kakhulu nomoya-mpilo.I-deoxidizer esetshenziswa kakhulu yi-ferromanganese, i-ferrosilicon, i-ferrotitanium, i-ferroaluminum, i-silicon calcium alloy, njll.

(4) Ipulasitiki

Umsebenzi wawo oyinhloko ukuthuthukisa i-plasticity, i-elasticity kanye ne-fluidity enkambweni ye-electrode ecindezelwa ukugqoka, ukuthuthukisa ikhwalithi yokugqoka ye-electrode, ukuze indawo ebushelelezi ye-electrode coating ingaqhekeki.Ngokuvamile khetha ukunwebeka okuthile, okushelelayo noma okumunca ngemva kwezici ezithile zokunwetshwa zezinto zokwakha, njenge-mica, udaka olumhlophe, i-titanium dioxide, i-talc, ingilazi yamanzi eqinile, i-cellulose, njll.

(5) I-ejenti yengxubevange

Isetshenziselwa ukunxephezela ukushiswa kwezakhi ze-alloying ohlelweni lokushisela kanye nokudlulisa izakhi ze-alloying ku-weld, ukuze kuqinisekiswe ukwakheka kwamakhemikhali kanye nezakhiwo zensimbi yokushisela.Ngokwesidingo sokukhetha izinhlobonhlobo zama-ferroalloys (njenge-ferromanganese, i-ferrosilicon, i-ferrochrome, insimbi nensimbi, i-ferric vanadium, i-ferric niobium, i-ferric boron, i-ferrosilicon yomhlaba engavamile, njll.) noma izinsimbi ezihlanzekile (njengensimbi ye-manganese, insimbi ye-chromium , i-nickel powder, i-tungsten powder, njll.).

(6) I-ejenti yokwenza i-slag

I-Welding ingakha izakhiwo ezithile ezingokomzimba namakhemikhali ze-slag encibilikisiwe, ivikele i-welding droplet kanye nensimbi ye-pool encibilikisiwe, ithuthukise ukwakheka kwe-weld, njenge-slagging ejenti yezinto zokusetshenziswa yimabula, i-fluorite, i-dolomite, i-magnesia, i-feldspar, udaka olumhlophe, i-mica, i-quartz. , i-rutile, i-titanium dioxide, i-ilmenite, njll.

(7) Isibopho

Izinto zokumboza ziboshwe ngokuqinile kumgogodla we-welding, futhi ukugqoka kwe-electrode kunamandla athile ngemva kokumisa.Enqubweni ye-welding metallurgy, akukho mphumela olimazayo ku-weld pool kanye nensimbi ye-weld.Izibophezelo ezivame ukusetshenziswa yi-sodium silicate (i-potassium, i-sodium ne-silicate ye-sodium exutshwe) kanye ne-phenolic resin, gum, njll.

Isikhathi sokuthumela: May-04-2023