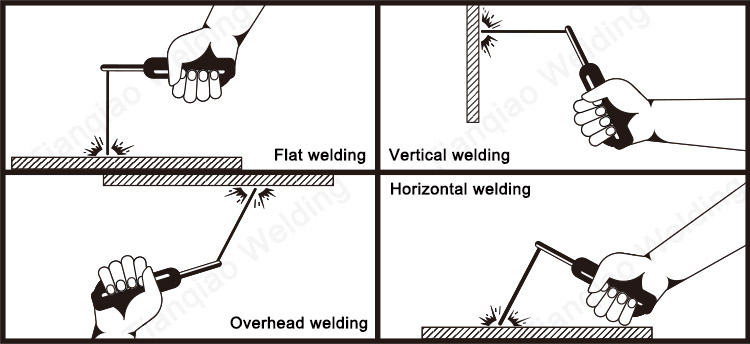

Isikhundla se-welding sibhekiselwa kuso lapho u-welding, isikhundla sendawo yesihlobo se-weld kuya ku-welder.

Umfanekiso 1. Tianqiao welding positon

Umfanekiso 1. Tianqiao welding positon

Kukhona i-flat welding, i-horizontal welding, i-vertical welding kanye ne-overhead welding.I-flat welding ibhekisela ekushiseni okuvundlile okwenziwa umshiseli ekhothamise ikhanda, ngakho kubizwa nangokuthi ukushisela phansi;ukuze i-weld ekuxhumaneni okumise okwe-T, ukushisela okumise okwe-T kuvame ukubekwa ku-45 ° ukuze kwakhiwe isikhundla sokushisela se-welding seam eyehlayo, ebizwa ngokuthi ukushisela umkhumbi.Ukushisela okuvundlile kubhekisela ekushiseleleni okuvundlile okwenziwa umshiseli cishe ngobude obufanayo nengalo.Ukushisela okuqondile kubhekisela ekushiseleleni okusuka phezulu kuya phezulu okwenziwe ngumshiseli.I-overhead welding ibhekisela ekushiseleleni komthungo ovundlile okwenziwa umshiseli obheke phezulu.I-flat welding iyona elula kakhulu yokuqinisekisa ikhwalithi yokushisela, i-welding enezingqimba ingeyesibili, i-welding eqondile ingeyesithathu, futhi i-overhead welding yiyona enzima kakhulu ukuqinisekisa ikhwalithi futhi kufanele igwenywe ngangokunokwenzeka.

Umfanekiso 2. Tianqiao welding flat

Umfanekiso 2. Tianqiao welding flat

Ukushisela okuyisicaba

Izici zokushisela ze-flat welding:

1. Insimbi yokushisela incike kakhulu esisindweni sayo ukuze idlulele echibini elincibilikisiwe.

2. Ukuma nensimbi yechibi elincibilikisiwe kulula ukuyigcina nokulawula.

3. Ukuze uthole izinsimbi zokushisela ezinobukhulu obufanayo, i-welding current endaweni ye-welding flat inkulu kunaleyo kwezinye izikhundla zokushisela, futhi ukusebenza kahle kokukhiqiza kuphezulu.

4. I-slag kanye nechibi elincibilikisiwe lijwayele ukuxuba, ikakhulukazi uma welding flat fillet welds, i-slag kulula ukuhola futhi yakha ukufakwa kwe-slag.

*Akulula ukuhlukanisa i-slag yenduku yokushisela ene-asidi nedamu elincibilikisiwe;lezi zinduku zokushisela ezine-alkali zicacile;izinga le-HG20581 lisho ngokucacile ukuthi izinduku zokushisela i-asidi azikwazi ukusetshenziswa ezitsheni ze-Class II ne-III.

5. Imingcele ye-welding engalungile kanye nokusebenza kungaholela kalula ekushiyekeni okufana ne-weld bead, i-undercut, kanye ne-welding deformation.

6. Uma uhlangothi olungemuva lwe-single-side welding lwakhiwe ngokukhululekile, i-weld yokuqala ijwayele izinqubo zokungena ezingalingani kanye nokubunjwa okungalungile emuva.

Izindawo zokuhlala ezengeziwe e-flat welding:

1. Ngokusho kobukhulu bepuleti, i-electrode yobubanzi obukhulu kanye ne-welding current enkulu ingasetshenziswa.

2. Lapho i-welding, induku yokushisela kanye ne-weldment yenza i-angle engu-60 ~ 80 °, futhi ukuhlukaniswa kwe-slag nensimbi ye-liquid kulawulwa ukuvimbela i-slag ukuthi ingabonakali kusengaphambili.

3. Uma ubukhulu bepuleti bungaphansi noma bulingana no-6mm, ukushisela isinqe esiyisicaba ngokuvamile kunohlobo lwe-I groove, futhi umphetho wokushisela wangaphambili kufanele ube ukushisela okufushane kwe-arc nge-electrode engu-φ3.2~4, futhi ukujula kokungena kungaba finyelela ku-2/3 wobukhulu bepuleti;ngaphambi kokuba i-back ivalwe, Akudingekile ukuhlanza izimpande (ngaphandle kwezakhiwo ezibalulekile), kodwa i-slag kufanele ihlanzwe futhi yamanje ingaba mkhulu.

4. Uma kunokuxutshwa okungacacile kwe-slag nensimbi ye-pool encibilikisiwe ku-butt flat welding, i-arc inganwetshwa, i-electrode ingatshekiswa phambili, futhi i-slag encibilikisiwe ingaphushwa ngemuva kwechibi elincibilikisiwe ukuze kuvinjelwe ukufakwa kwe-slag.

5. Uma ushisela ama-welds athambekele avundlile, ukushisela i-upslope kufanele kusetshenziselwe ukuvimbela ukufakwa kwe-slag kanye nechibi elincibilikisiwe ukuthi liqhubekele phambili ukugwema ukufakwa kwe-slag.

6. Uma usebenzisa i-multi-layer kanye ne-multi-pass welding, qaphela inani lokudlula kwe-welding nokulandelana kwe-welding, futhi ungqimba ngalunye akufanele ludlule u-4 ~ 5mm.

7. Okwamajoyinti ashiselwe i-angle eyisicaba ohlobo lwe-T, ukuhlanganisa ekhoneni, nokuhlanganisa okuhambisanayo, uma ubukhulu bamapuleti amabili buhlukile, i-engeli yenduku yokushisela kufanele ilungiswe ukuze iphambukise i-arc ohlangothini olulodwa lwepuleti eliwugqinsi, ukuze amapuleti amabili afudunyezwe ngokulinganayo.

8. Ukukhetha okulungile kwendlela yokuthumela

(1) Uma ukujiya kokushisela kungaphansi noma kulingana no-6mm, thayipha i-groove butt flat welding.Lapho i-welding enezinhlangothi ezimbili yamukelwa, i-welding seam yangaphambili ithatha umugqa oqondile, ohamba kancane;i-back welding seam nayo ithatha umugqa oqondile, futhi i-welding current ikhudlwana kancane., Ngokushesha.

(2) Uma ubukhulu bepuleti bungu-≤6mm, lapho uvula ezinye izinhlobo zemifula, i-welding ye-multi-layer noma i-multi-layer multi-pass welding ingasetshenziswa.Isendlalelo sokuqala se-welding engezansi kufanele sisebenzise i-electrode yamanje encane, yamanje encane evamile, umugqa oqondile noma i-sawtooth.Ukushisela ibha yezokuthutha yomumo.Ukuze ugcwalise i-welding yengqimba, i-electrode enkulu yobubanzi kanye ne-arc welding emfushane ene-welding yamanje enkulu ingakhethwa.

(3) Uma ubukhulu bomlenze we-flat fillet welding ye-T-joint ingaphansi kwe-6mm, i-welding single-layer ingasetshenziswa, futhi i-linear, i-oblique ring noma indlela yokuthutha emise okwezigzag ingasetshenziswa;lapho ubukhulu bomlenze bukhulu, i-welding ye-multi-layer noma i-multi-layer welding kufanele isetshenziswe.I-Multi-pass welding, i-welding engezansi isebenzisa indlela yokuthutha ye-linear strip, futhi isendlalelo sokugcwalisa singakhetha i-oblique sawtooth noma i-oblique circular strip transport.

(4) Ngokuvamile, i-multi-layer kanye ne-multi-pass welding kufanele ihlanganiswe ngendlela yokuthutha yomugqa oqondile.

Ama-electrode ensimbi athambile alungele ukushisela okuyisicabaAWS E6013, AWS E6010, AWS E6011, AWS E7018.

Umfanekiso 3. Tianqiao welding mpo

Umfanekiso 3. Tianqiao welding mpo

Ukushisela okuqondile

Izici zokushisela ze-welding eqondile:

1. Insimbi ye-pool encibilikisiwe kanye ne-slag encibilikisiwe iwa ngenxa yesisindo sayo futhi kulula ukuyihlukanisa.

2. Uma izinga lokushisa lechibi elincibilikisiwe liphezulu kakhulu, insimbi yechibi elincibilikisiwe kulula ukuconsa ukuze yenze iziphambeko ezifana nobuhlalu obushiselayo, i-undercut, ukufakwa kwe-slag, njll., futhi i-weld ayilingani.

3. Umsuka we-T-joint weld kulula ukwenza ukungena okungaphelele.

4. Izinga lokungena kulula ukuliqonda.

5. Ukukhiqiza kwe-Welding kungaphansi kune-flat welding.

Amaphuzu ayinhloko we-welding eqondile:

1. Gcina i-angle yenduku yokushisela efanele;

2. Ekukhiqizeni, i-welding eqondile eqondile ivame ukusetshenziswa, futhi i-welding eqondile mpo idinga izinduku zokushisela ezikhethekile ukuze kuqinisekiswe ikhwalithi ye-weld.I-welding current ye-welding up vertical up incane ngo-10~15% kunaleyo yokushisela isicaba, futhi i-electrode diameter encane (<φ4mm) kufanele ikhethwe.

3. Sebenzisa i-arc welding emfushane ukuze unciphise ibanga ukusuka econsi kuya echibini elincibilikisiwe.

4. Sebenzisa indlela yokuthumela efanele.

(1) Inhlanganisela yezinqe ze-T-groove (evame ukusetshenziselwa amapuleti amancane) lapho ukushiselwa okuqondile kwenziwa, ukushisela okumile okumazombezombe okumise okwecwephe kuyasetshenziswa, kanti ubude be-arc obukhulu abukho ngaphezu kuka-6mm.

(2) Lapho uvula ezinye izinhlobo ze-groove butt welding welding eqondile, ungqimba lokuqala lwe-weld luvamise ukushiselwa nge-welding ephukile, emise okwenyanga emise okukanxantathu nokujikijela okuncane.Kamuva, ungqimba ngalunye lungasetshenziselwa imithende ye-crescent noma ye-zigzag.

(3) Ngesikhathi sokushisela okuqondile kwamajoyinti amise okwe-T, induku yokushisela kufanele ibe nesikhathi esifanelekile sokuhlala ezinhlangothini zombili nasemakhoneni aphezulu omthungo wokushisela, futhi i-swing amplitude yenduku yokushisela akufanele ibe nkulu kunobubanzi be-welding. umthungo.Ukusebenza kwenduku yokushisela kuyefana nokwenye i-welding eqondile enemifantu.

(4) Lapho ushisela isendlalelo sekhava, ukuma kwendawo yokushisela kunqunywa indlela yokuthutha.Imichilo emise okwe-Crescent ingasetshenziselwa ukushisela izindawo zomthungo ezinezidingo eziphakeme;ama-zigzag strips angasetshenziselwa izindawo eziyisicaba (isimo se-concave phakathi nendawo sihlobene nesikhathi sokumisa okwesikhashana).

Ama-electrode ensimbi athambile alungele ukushisela mpoAWS E6013, AWS E6010, AWS E6011, AWS E7018, ikakhulukaziE6011ilungele ukushisela i-up-bottom up-bottom.

Umfanekiso 4. Tianqiao overhead welding

Ukushisela ngaphezulu

Izici zokushisela ze-overhead welding:

1. Insimbi encibilikisiwe iwela ngenxa yamandla adonsela phansi, futhi ukuma nobukhulu bechibi elincibilikisiwe akufanele kulawulwe.

2. Kunzima ukuthutha umugqa, futhi ubuso be-weldment abufanele ukuthungatha.

3. Amaphutha afana nokufakwa kwe-slag, ukungena okungaphelele, ubuhlalu be-weld kanye nokubunjwa okungalungile kwe-weld kulula ukuvela.

4. Insimbi encibilikisiwe yokushisela iyasakazeka futhi isakazeke, okungase kubangele kalula izingozi ezishisayo.

5. Ukusebenza kahle kwe-overhead welding kuphansi kunezinye izikhundla.

Izindawo zokushisela ze-overhead welding:

1. Ukushisela okungaphezulu kwe-butt welds.Lapho ubukhulu be-weldment bungaphansi noma bulingana no-4mm, sebenzisa ama-grooves ohlobo lwe-I futhi usebenzise izinduku zokushisela ezingu-φ3.2mm ezine-welding current emaphakathi;lapho ukushuba kokushisela kukhulu noma kulingana no-5mm, kufanele kusetshenziswe ungqimba oluningi kanye ne-multi-pass welding.

2. Umthungo wokushisela wejoyinti elimise okwe-T uwukushisela ngaphezulu.Uma unyawo lwe-welding lungaphansi kuka-8mm, kufanele kusetshenziswe i-welding eyodwa-ungqimba, futhi uma unyawo lokushisela lukhulu kuno-8mm, kufanele kusetshenziswe i-multi-layer kanye ne-multi-pass welding.

3. Ngokwesimo esithile, sebenzisa indlela yokuthutha eyiyo:

(1) Uma usayizi wonyawo lokushisela mncane, uhlobo oluphindaphindayo oluwumugqa noma oluwumugqa lusetshenziselwa ukuqedela ukushisela okunongqimba olulodwa;lapho ubukhulu bonyawo lwe-welding bukhulu, i-welding ye-multi-layer noma i-multi-layer multi-pass welding ingasetshenziswa, futhi isendlalelo sokuqala kufanele sisetshenziswe ukuthutha komugqa oqondile, ezinye izendlalelo zingakhetha unxantathu oblique noma indlela yokuthutha indandatho ye-oblique.

(2) Kungakhathaliseki ukuthi yiluphi uhlobo lwendlela yokuthutha eyamukelwayo, insimbi yokushisela akufanele ibe ningi kakhulu njalo lapho idlula echibini elincibilikisiwe.

Ama-electrode ensimbi athambile alungele ukushisela phezuluAWS E6013, I-AWS E6010, AWS E6011, AWS E7018

Umfanekiso 5. Tianqiao Welding enezingqimba

Umfanekiso 5. Tianqiao Welding enezingqimba

Ukushisela okuvundlile

Izici zokushisela ze-welding enezingqimba:

1. Insimbi encibilikisiwe iwela kalula emseleni ngenxa yesisindo sayo, ibangele ukonakala kwe-undercut ohlangothini olungaphezulu, kanye nobuhlalu obushicilele obumise okwe-teardrop noma amaphutha okungena angaphelele ohlangothini olungezansi.

2. Insimbi encibilikisiwe kanye ne-slag kulula ukuhlukanisa, kufana nokushisela okuqondile.

Amaphuzu abalulekile we-welding evundlile:

1. Imisele yokushisela evundlile ehlangene yezinqe ngokuvamile imise okwe-V noma emise okwe-K, amalunga ezinqe anogqinsi lwepuleti elingu-3~4mm angashiselwa nhlangothi zombili ngemisele yohlobo I.

2. Sebenzisa induku ye-welding encane, i-welding current incane kune-flat welding, ukusebenza kwe-arc okufushane, kungalawula kangcono ukuhamba kwensimbi encibilikisiwe.

3. Uma ufaka amapuleti aminyene, ngaphezu kwe-weld engezansi, kuhle ukusebenzisa i-multi-layer kanye ne-multi-pass welding.

4. Ukuze uthole i-welding ye-multi-layer kanye ne-multi-pass welding, ukunakwa okukhethekile kufanele kukhokhwe ekulawuleni ibanga lokudlulana phakathi kwama-weld pass.Kwi-welding ngayinye egqagqene, qala ukushisela ku-1/3 ye-weld yangaphambilini ukuvimbela ukungalingani.

5. Ngokwesimo esithile, gcina i-angle yenduku yokushisela efanele, futhi ijubane lokushisela kufanele libe li-blocky kancane futhi lifane.

6. Sebenzisa indlela yokuthumela efanele.

(1) Ngohlobo lwe-I butt welding evundlile, kungcono ukusebenzisa indlela ye-linear strip ephindaphindayo kumthungo ongaphambili wokushisela;imichilo eyindilinga eqondile noma emincane e-oblique kufanele isetshenziselwe izingxenye eziwugqinsi, kanye namapheshana aqondile ohlangothini olungemuva, futhi i-welding current ingakhuliswa ngendlela efanele.

(2) Sebenzisa enye i-bevel butt welding evundlile.Uma igebe lincane, i-welding engezansi ingasebenzisa imichilo eqondile;lapho igebe likhulu, ungqimba olungezansi luthatha imichilo yomugqa ephindaphindayo;lapho ezinye izendlalelo ziyi-multi-layer welding, umugqa othambekele ungasetshenziswa.Ukuthutha ngomugqa oqondile kufanele kusetshenziselwe ukuthuthwa okuyindilinga kwamapheshana kanye ne-multi-layer kanye ne-multi-pass welding.

Ama-electrode ensimbi athambile alungele ukushisela ovundlileAWS E6013, AWS E6010, AWS E6011, AWS E7018

Isikhathi sokuthumela: Jul-21-2021