Niniwelding insimbi engagqwali, ukusebenza kwe-electrode kumele kuhambisane nenjongo yensimbi engagqwali.I-electrode yensimbi engagqwali kufanele ikhethwe ngokuya ngesisekelo sensimbi nezimo zokusebenza (kuhlanganise nezinga lokushisa lokusebenza, indawo yokuxhumana, njll.).

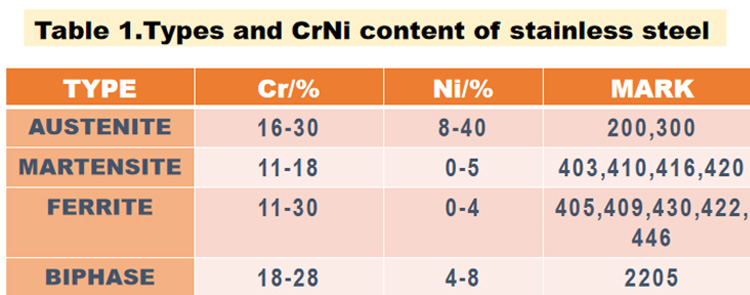

Izinhlobo ezine zensimbi engagqwali kanye nezakhi ze-alloying zisetshenziswa

Insimbi engagqwali ingahlukaniswa ngezinhlobo ezine: i-Austenitic, i-martensitic, i-ferritic ne-biphase insimbi engagqwali, njengoba kukhonjisiwe kuThebula 1.

Lokhu kusekelwe esakhiweni se-metallographic sensimbi engagqwali ekamelweni lokushisa.Lapho insimbi emnene ishiselwa1550° F, ukwakheka kuyashintsha kusuka esigabeni se-ferrite sezinga lokushisa kuya esigabeni se-austenitic.Uma selehlile, isakhiwo sensimbi esithambile siguqulwa sibe yi-ferrite.Izakhiwo ze-Austenitic ezikhona emazingeni okushisa aphezulu azinawo uzibuthe futhi zinamandla amancane nokuqina kunezakhiwo ze-ferrite zegumbi.

Indlela yokukhetha i-welding yensimbi engagqwali efanele?

Uma into eyisisekelo ifana, umthetho wokuqala uthi "fanisa into eyisisekelo".Isibonelo, khetha izinto zokushisela310 or 316insimbi engagqwali.

Ekushiseleni izinto ezingafani, umbandela wokukhetha into eyisisekelo enokuqukethwe okuphezulu kwe-alloying iyalandelwa.Isibonelo, uma i-304 noma i-316 insimbi engagqwali ishiselwe, khetha uhlobo316.

Kodwa futhi kukhona abaningi abangalandeli isimiso "sesisekelo esihambisanayo" sezimo ezikhethekile, ngakho-ke kuyadingeka "ukubonisana netafula lokukhetha izinto zokushisela".Ngokwesibonelo, thayipha304insimbi engagqwali iyinsimbi eyisisekelo evamile, kodwa alukho Uhlobo304i-electrode.

Uma izinto zokushisela zihambisana nesisekelo sezinto, indlela yokukhetha izinto zokushisela ukuze zishise304insimbi engagqwali?

Uma welding304insimbi engagqwali, sebenzisa uhlobo308welding impahla, ngoba izakhi ezengeziwe ku308insimbi engagqwali ingakwazi ukuzinzisa kangcono indawo yokushisela.

308I-L nayo iyindlela eyamukelekayo.U-L usho okuqukethwe kwekhabhoni ephansi,3Okuqukethwe kwekhabhoni yensimbi engagqwali engu-XXL ≤0.03%, kanye nezinga3XXinsimbi engagqwali ingaqukatha kufika0.08%okuqukethwe kwekhabhoni.

Ngenxa yokuthi ukushisela okumise okuka-L kungokwesigaba esifanayo njengokushisela okungaka-L, abakhiqizi kufanele bacabangele ngokukhethekile ukusebenzisa ukushisela okumise okwe-L ngoba okuqukethwe kwayo kwekhabhoni ephansi kunciphisa ukugqwala kwe-intergranular (bona Umfanekiso 1).

Indlela yokushisela insimbi engagqwali ne-carbon steel?

Ukuze kuncishiswe izindleko, ezinye izakhiwo zishisela ungqimba lokumelana nokugqwala ebusweni bensimbi ye-carbon.Uma ushisela into eyisisekelo ngaphandle kwezakhi ze-alloying enezinto eziyisisekelo ezinezici ze-alloying, sebenzisa i-welding material enokuqukethwe okuphezulu kwe-alloying ukuze ulinganise izinga lokuhlanjululwa ekushiseni.

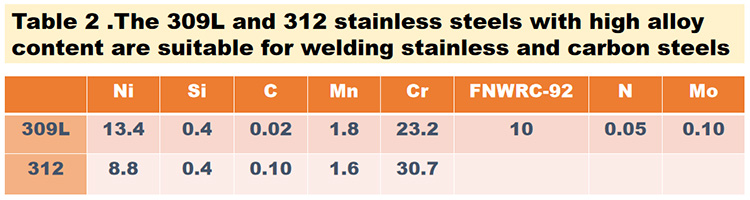

Lapho Welding carbon steel nge304 or 316insimbi engagqwali nezinye insimbi engagqwali engafani (bheka Ithebula 2),309L impahla yokushiselakufanele kucatshangelwe ezimweni eziningi.Uma ufuna ukuthola okuqukethwe okuphezulu kwe-Cr, khetha uhlobo312.

Imuphi umsebenzi wokuhlanza ofanelekile wangaphambi kokushisela?

Uma ushisela ngezinye izinto, qala ngokukhipha amafutha, amamaki nothuli ngesincibilikidi esingena-chlorine.Ngaphezu kwalokho, into yokuqala okufanele uyiqaphele lapho ushisela insimbi engagqwali ukugwema ukungcoliswa yi-carbon steel futhi kuthinte ukumelana nokugqwala.Ezinye izinkampani zigcina insimbi engagqwali ne-carbon steel ngokuhlukana ukuze zigweme ukungcoliswa.Sebenzisa amasondo okugaya akhethekile namabhulashi ensimbi engagqwali lapho uhlanza indawo ezungeze umsele.Kwesinye isikhathi ilunga lidinga ukuhlanzwa okwesibili.Ngenxa yokuthi ukusebenza kwesinxephezelo se-electrode ye-stainless steel welding kunzima kakhulu kune-carbon steel welding, ukuhlanza okuhlangene kubaluleke kakhulu.

Isikhathi sokuthumela: May-09-2023