I-Professional China China Welding Flux Powder ye-H-Beam Welding

I-Excellent 1st, kanye ne-Client Supreme iyisiqondiso sethu sokuletha umhlinzeki ofanelekayo kumathemba ethu.Namuhla, besifuna okusemandleni ethu ukuba ngokuqinisekile sibe omunye wabathekelisi abaphumelela kakhulu emkhakheni wethu ukuze sihlangabezane nabathengi abadingekayo kakhulu ku-Professional China China Welding Flux Powder. ye-H-Beam Welding, Uma uthakasele cishe kunoma yiziphi izinto zethu noma ungathanda ukuxoxa ngokuthenga ngokwezifiso, akufanele uzizwe ungekho zindleko zokusibamba.

I-Excellent 1st, kanye ne-Client Supreme iyisiqondiso sethu sokuletha umhlinzeki ofanelekayo kumathemba ethu.Kulezi zinsuku, besifuna okusemandleni ethu ukuba ngokuqinisekile sibe omunye wabathekelisi abaphumelela kakhulu emkhakheni wethu ukuze sihlangabezane nabathengi abadinga kakhuluI-China Submerged Arc Welding Flux, i-welding flux, Inhloso yethu ukusiza amakhasimende ukuthi enze inzuzo eyengeziwe futhi afeze imigomo yawo.Ngokusebenza kanzima okuningi, sisungula ubudlelwano bebhizinisi besikhathi eside namakhasimende amaningi emhlabeni jikelele, futhi sizuze impumelelo yokuwina.Sizoqhubeka nokwenza umzamo wethu omuhle kakhulu wokukusiza futhi sikunelise!Siyakwamukela ngokuzithoba ukuthi uhlanganyele nathi!

Izicelo:

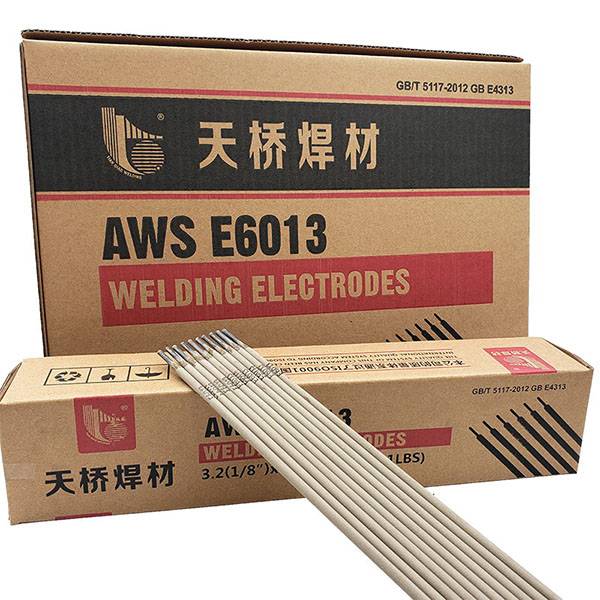

I-E6013 impushana yokushisela yokwenza i-electrode yokushisela, okuwuhlobo lwe-carbon steel electrode enohlobo lwe-iron powder titania.AC/DC.I-welding yendawo yonke.Inokusebenza okuhle kakhulu kwe-welding futhi cishe ayinawo ama-spatter.Inokuvutha kabusha kalula, ukubola okuhle kwe-slag, ukubukeka kwe-welding okubushelelezi.Ibanga elivamile kanye nebanga le-rutile ongalikhetha.

Izici:

1.Isiteleka esisheshayo kanye nokushaya okulula nokususwa kalula kwe-slag

2.Ukusebenza kwe-arc okuzinzile kanye nokuphazamiseka okuncane kwe-arc

3.Ukubukeka okubushelelezi nokucwebezelayo & nezakhiwo ezinhle kakhulu zemishini

4. Ukusebenza okuphezulu kanye namanani omthelela aphezulu ku -30c.

5. Amazinga aphezulu e-deposit

6. Ukumelana nokuqhekeka okuhle kakhulu nokusebenza kwe-x-ray

7. Ukupakisha: 300kgs isikhwama damproof emaphaketheni;noma njengoba ubudinga

Qaphela:

1.I-Electrode kumele ivunywe ngu-350-380℃ ihora elingu-1 ngaphambi kokushisela, yomisa i-electrode uma uyisebenzisa.

2. Ukugqwala, amafutha, amanzi nokunye ukungcola kwe-weld kufanele kususwe ngaphambi kokushisela.

3.Kumelwe usebenzise i-arc welding emfushane, ama-swings akufanele abe mkhulu kakhulu, ukushisela ubuhlalu obuncane kufanelekile.

4. Ukuze uvimbele ukukhiqiza i-arc porosity, ipuleti le-arc kufanele lamukelwe noma lisebenzise indlela yokubuyisela yokushisela i-arc.

Ukwakhiwa Kwekhemikhali:

| Izinto | I-TiO2 | I-AL2O3 | SiO2 | Mn | I-CaO+MgO | Okuphilayo | Okunye |

| Umphumela wangempela | 42 | 4.5 | 28 | 9 | 10.5 | 4 | 2 |

I-Welding electorde powder ye-E7018, E6011, E6010, E7024, njll iyatholakala.Pls xhumana nathi ukuze uthole imininingwane eyengeziwe.

Izidingo zobuchwepheshe zokucubungula:

Izingxenye zokushisela ezibalulekile kufanele zimakwe ngokucacile ngokuhambisana nemithetho efanele lapho ulungiselela imininingwane yenqubo yokushisela.

Ukuhlanganisa isikhunta (i-assembly fixture) yezingxenye ezishiselwe, inani le-welding shrinkage kufanele licatshangelwe.Kufanele kuqinisekiswe ukuthi ukubekezelelana kwezingxenye ezishiselwe kungaphakathi kwezidingo zokuklama.

Ngaphambi kokuhlanganisa, susa ukugqwala, uwoyela, uthuli kanye nomswakama endaweni engekho ngaphansi kuka-25mm ezinhlangothini zombili ze-weld.Kumashisela abalulekile ensimbi yesakhiwo se-alloy ephansi, isikali se-oxide kufanele sisuswe.

Igebe lokuhlanganisa kufanele lilawulwe ngesikhathi sokuhlanganisa.Igebe le-butt welds liyi-2 ~ 3mm, futhi igebe lamashisela e-fillet ngu-0 ~ 2mm.Uma igebe lasendaweni likhulu kakhulu, zama ukulinciphisa libe ngusayizi oshiwo.Kunqatshelwe ngokuphelele ukwengeza ama-fillers kugebe, futhi ukubhanqa okuqinile akuvunyelwe ukunciphisa ukucindezeleka okusele ezingxenyeni ezishiselwe.

Izinto zokushisela kanye nemingcele yenqubo esetshenziswa ekushiseleleni i-tack tack izofana nezidingo ze-weld ezisemthethweni.

Ukusebenza kwe-welding kungenziwa kuphela ngemuva kokuthi izingxenye ze-welding ziphumelele ukuhlolwa komhlangano.

Okwezinto ezisetshenziswayo ezintsha nezinqubo ezintsha, ukuhlolwa kwenqubo kufanele kwenziwe futhi zingasetshenziswa kuphela ngemva kokuba seziqeqeshiwe.

I-slag yokushisela kanye nokukhubazeka empandeni ye-weld kufanele kususwe ngaphambi kokushisela i-weld ehlanekezayo ye-weld kanye namanye ama-weld a-grooved.

I-Welding ingenziwa kuphela ngemva kokuhlanza.

Ngaphambi kwe-welding, akuvunyelwe ukuqala ukuthungela kwe-arc nokuhlola ukulungiswa kwamanje endaweni engashisi.Ngemuva kwe-weld, ubuso be-weld kufanele buhlanzwe futhi bomiswe.

I-Net, yezingxenye ezibalulekile ze-welding zezingxenye ezibalulekile zokushisela, uphawu lwe-welder kufanele luphawulwe endaweni efanele ngemva kokushisela.

Kumapuleti ensimbi anogqinsi lwe-0.3 ~ 4mm, izindlela zokushisela ezifana ne-gas metal arc welding noma i-argon tungsten arc welding isetshenziswa kakhulu.

Ukuze kufakwe i-welding yezingxenye zensimbi ezingafani, ama-electrode, izintambo kanye nama-fluxes wezinga elifanayo lamandla kufanele kukhethwe.

Uma welding low-alloy structural steel, akufanelekile ukuyeka phakathi, bese uzama ukuqedela ukushisela ngesikhathi esisodwa;ngesikhathi sokushisela okunezingqimba eziningi, amalunga phakathi kwezingqimba kufanele anyakaze futhi izinga lokushisa phakathi kwezingqimba lilawulwe phakathi kuka-250 ~ 300℃.Ngaphambi kokushisela ungqimba olulandelayo lwe-welding seam, kufanele luhlanzwe.Hlola ukushisela kwesendlalelo esingaphezulu ukuze uqinisekise ukuthi azikho iziphambeko.I-Excellent 1st, futhi I-Client Supreme iyisiqondiso sethu sokuletha umhlinzeki ofanelekayo kuma-prospects ethu.Kulezi zinsuku, besifuna okusemandleni ethu ukuba ngokuqinisekile sibe omunye wabathekelisi abaphumelela kakhulu. ngokwesiyalo sethu ukuhlangabezana nabathengi okudingeka kakhulu ku-Professional China China Welding Flux Powder ye-H-Beam Welding, Uma uthakasele cishe kunoma iyiphi yezinto zethu noma ungathanda ukuxoxa ngokuthenga ngokwezifiso, kufanele uzizwe ungekho zindleko zokubamba. thina.

I-Professional ChinaI-China Submerged Arc Welding Flux, I-Welding Flux, Inhloso yethu ukusiza amakhasimende ukuthi enze inzuzo eyengeziwe futhi afeze imigomo yawo.Ngokusebenza kanzima okuningi, sisungula ubudlelwano bebhizinisi besikhathi eside namakhasimende amaningi emhlabeni jikelele, futhi sizuze impumelelo yokuwina.Sizoqhubeka nokwenza umzamo wethu omuhle kakhulu wokukusiza futhi sikunelise!Siyakwamukela ngokuzithoba ukuthi uhlanganyele nathi!