I-Shielded Metal Arc Welding (efushanisiwe njenge-SMAW).Isimiso siwukuthi: i-arc ikhiqizwa phakathi kwe-electrode eboshwe kanye nesisekelo sensimbi, futhi indlela yokushisela isebenzisa ukushisa kwe-arc ukuncibilikisa i-electrode nesisekelo sensimbi.Isendlalelo sangaphandle se-electrode simbozwe nge-welding flux futhi siyancibilika lapho sichayeka ekushiseni, esinemisebenzi yokusimamisa i-arc, ukwakha i-slag, i-deoxidizing, kanye nokucwengisiswa.Ngenxa yokuthi idinga imishini elula nokusebenza okuguquguqukayo, ingafakwa kalula kuma-welds akhiwe izikhundla ezahlukene kanye namalunga ahlukene emkhathini.Ngakho-ke, lisasetshenziswa kabanzi okwamanje.

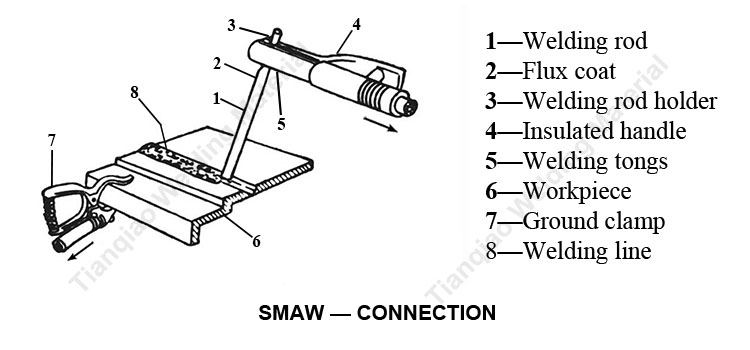

Umfanekiso 1: I-Shielded Metal Arc Welding-connection

I-arc welding ye-manual iboniswa emfanekisweni:

Ngaphambi kokushisela, xhuma i-workpiece eshiselwe kanye nezindlawu zokushisela ezigxotsheni ezimbili zomshini wokushisela kagesi bese ubopha induku yokushisela ngezindlawu zokushisela.Ngesikhathi sokushisela, induku ye-welding kanye ne-workpiece ithintana ngokushesha, yenza isifunda esifushane, bese ihlukaniswa ibanga elithile (cishe 2-4mm), futhi i-arc ivutha.

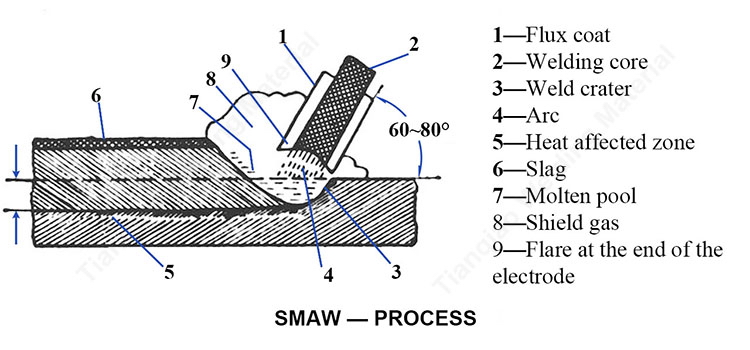

Umfanekiso 2: I-Shielded Metal Arc Welding-inqubo

I-workpiece ngaphansi kwe-arc iyancibilika ngokushesha ukuze yakhe i-semi-oval pool encibilikisiwe.Ngemva kokuba i-electrode coating incibilike, ingxenye yayo iba igesi ezungeza i-arc ukuze ihlukanise nomoya, ngaleyo ndlela ivikele insimbi ewuketshezi ku-oxygen ne-nitrogen;ingxenye yawo iba i-slag encibilikisiwe, noma ifuthwe echibini elincibilikisiwe iyodwa, noma incibilike ngomongo Amaconsi ancibilikisiwe ensimbi ewuketshezi afuthwe echibini elincibilikisiwe ndawonye.

Ku-arc nasechibini elincibilikisiwe, insimbi ewuketshezi, i-slag ne-arc gas izobhekana nezinguquko ezithile zomzimba nezamakhemikhali enye kwenye, njengokuhlakazeka kwegesi kunsimbi ewuketshezi kanye nokusabela kokunciphisa i-oxidation.Igesi ne-slag echibini elincibilikisiwe kuntanta phezulu ngenxa yesisindo sayo esilula.Lapho i-arc isusiwe, izinga lokushisa liyehla futhi insimbi ne-slag kuzoqina ngokulandelana.Ngale ndlela, izingcezu ezimbili zensimbi zihlanganiswa nensimbi encibilikisiwe necwebezelayo.Ngenxa yokuthi ukuncipha kwe-slag kuhlukile kweyensimbi, izoshibilika egobolondweni le-slag kanye nomngcele wensimbi, futhi igobolondo le-slag lingase liwe ngokuzenzakalelayo, noma liwe ngemva kokushaywa, futhi i-weld weld seam enezikali zezinhlanzi. zingavezwa.

Imishini eyinhloko ye-arc welding manual ingumshini wokushisela kagesi.Umshini wokushisela ugesi ungumthombo wamandla okhiqiza i-arc yokushisela, futhi kunezinhlobo ezimbili ze-AC ne-DC.Njengamanje, kunezinhlobo eziningi zemishini yokushisela kagesi ekhiqizwa eChina, engahlukaniswa ngemishini yokushisela kagesi ye-AC kanye nemishini yokushisela kagesi ye-DC ngokusho kwesakhiwo sayo.

Kunezindlela ezimbili ezihlukene zokuxhuma zemishini yokushisela ye-DC.Uma i-electrode ixhunywe ku-electrode engalungile futhi i-workpiece ixhunywe ku-electrode enhle, iyindlela yokuxhumana enhle;okuphambene indlela yokuxhumana ehlanekezelwe.Ngokuvamile, lapho ushisela nge-alkaline low-hydrogen electrode (njengeE7018, E7016), ukuze kushiswe i-arc ngokuzinzile, kunqunyelwe ukusebenzisa indlela yokuxhuma i-DC reverse;lapho usebenzisa i-acid electrode (njengeI-E6013, J422) ukushisela amapuleti ensimbi aminyene, indlela yokuxhuma phambili isetshenziswa, ngoba ingxenye ye-anode Izinga lokushisa liphakeme kunengxenye ye-cathode, futhi indlela yokuxhuma phambili ingathola ukujula okukhulu kokungena;lapho kushiswa amapuleti ensimbi emincane nezinsimbi ezingezona ayoni, kusetshenziswa indlela yokuxhumana ehlehlayo.Lapho ushisela nge-alternating current, njengoba i-polarity ishintsha ngokuhlukile, asikho isidingo sokukhetha uxhumano lwe-polarity.

Impahla yokushisela yokushisela okwenziwa ngesandla iyinduku yokushisela kagesi, equkethe insimbi eyinsimbi kanye nesimbozo esingaphandle kwenkango yensimbi (Futhi bonaUkwakheka kwe-electrode yokushisela).

I-Welding core

Indima yensimbi yensimbi (i-welding core) ngokuyinhloko ukuqhuba ugesi futhi yakha insimbi efakwe ngokubunjwa okuthile ekupheleni kwe-electrode.I-welding core ingenziwa ngezinsimbi ezihlukahlukene.Ukwakheka kwe-welding core kuthinta ngqo ukwakheka nokusebenza kwensimbi efakiwe.Ngakho-ke, i-welding core iyadingeka ukuze kuncishiswe okuqukethwe kwezinto eziyingozi.Ngaphezu kokukhawulela i-S no-P, ezinye izinduku zokushisela ziye zadinga umgogodla wokushisela ukuze ulawule njenge-As, Sb, Sn nezinye izakhi.

Umfanekiso 3: Tianqiao welding electrode E6013

Ijazi le-Flux

I-Electrode coating ingabizwa nangokuthi upende.Inhloso eyinhloko yokuyimboza kumgogodla ukwenza lula ukusebenza kwe-welding nokuqinisekisa ukuthi insimbi efakiwe inokwakheka nokusebenza okuthile.Izingubo ze-Electrode zingaxutshwa namakhulu ezimpushana zempahla eluhlaza njengama-oxides, amakhabhoni, ama-silicates, ama-organics, ama-fluoride, ama-ferroalloys kanye nemikhiqizo yamakhemikhali ngokwesilinganiso esithile sefomula.Izinto ezisetshenziswayo ezahlukahlukene zingahlukaniswa ngezigaba ezilandelayo ngokuya ngendima yazo ekufakweni kwe-electrode:

1. I-Stabilizer yenza i-electrode ibe lula ukuqala i-arc futhi ingagcina i-arc ivutha ngokuzinzile ngesikhathi senqubo yokushisela.Noma iyiphi into okulula ukuyifaka i-ionize ingazinzisa i-arc.Ngokuvamile, kusetshenziswa izinhlanganisela zezinsimbi ze-alkali nezinsimbi zomhlaba ezine-alkaline, njenge-potassium carbonate, i-sodium carbonate, imabula, njll.

2. I-ejenti eyenza i-slag ingakha i-slag encibilikisiwe enezici ezithile zomzimba namakhemikhali ngesikhathi sokushisela, emboza ubuso bensimbi encibilikisiwe, ivikela ichibi lokushisela futhi ithuthukise ukuma kwe-weld.

3. I-Deoxidizer ngokusebenzisa ukusabela kwamakhemikhali e-metallurgical kwinqubo yokushisela ukunciphisa okuqukethwe komoya-mpilo ensimbi yokushisela futhi kuthuthukiswe izakhiwo zemishini ze-weld.Ama-deoxidizer ayinhloko yi-ferromanganese, i-ferrosilicon, ne-ferro-titanium.

4. I-ejenti ekhiqiza igesi ingahlukanisa futhi ikhulule igesi ngaphansi kwesenzo se-arc lokushisa eliphezulu ukuvikela i-arc nechibi elincibilikisiwe futhi kuvimbele ukungena kwe-oksijeni ne-nitrogen emoyeni ozungezile.

5. I-ejenti ye-alloying Isetshenziselwa ukunxephezela ukushiswa kwezakhi ze-alloy kanye nokuguqulwa kwezakhi ze-alloy ekushiseni ngesikhathi senqubo yokushisela ukuze kuqinisekiswe ukuthi insimbi ye-weld ithola ukwakheka kwamakhemikhali okudingekayo nokusebenza.

6. I-Plasticizing Lubricant Khulisa i-plasticity, i-slippage kanye ne-fluidity ye-powder yokugqoka enkambweni yokucindezela induku yokushisela ukuze kuthuthukiswe ikhwalithi yokucindezela yenduku yokushisela futhi unciphise i-eccentricity.

7. Ama-Adhesives Yenza i-powder yokugqoka ibe ne-viscosity ethile ngesikhathi senqubo yokucindezela ukucindezela, ingakwazi ukubopha ngokuqinile ne-welding core, futhi wenze i-welding rod coating ibe namandla athile ngemva kokumisa.

Isikhathi sokuthumela: Jul-27-2021